| Raw material : | |

|---|---|

| Height : | |

| Welding distance: | |

| Availability: | |

| Quantity: | |

ZL-TGGS

zhongloo

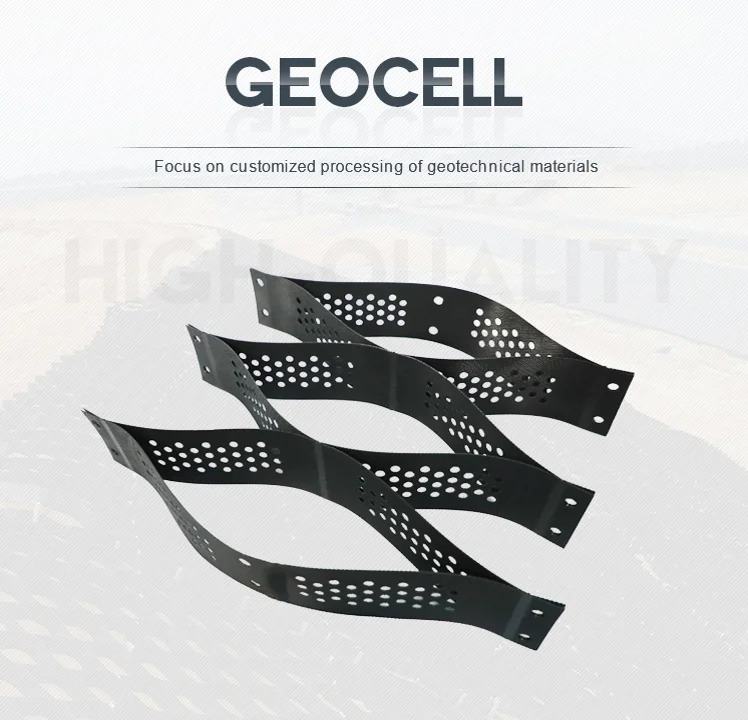

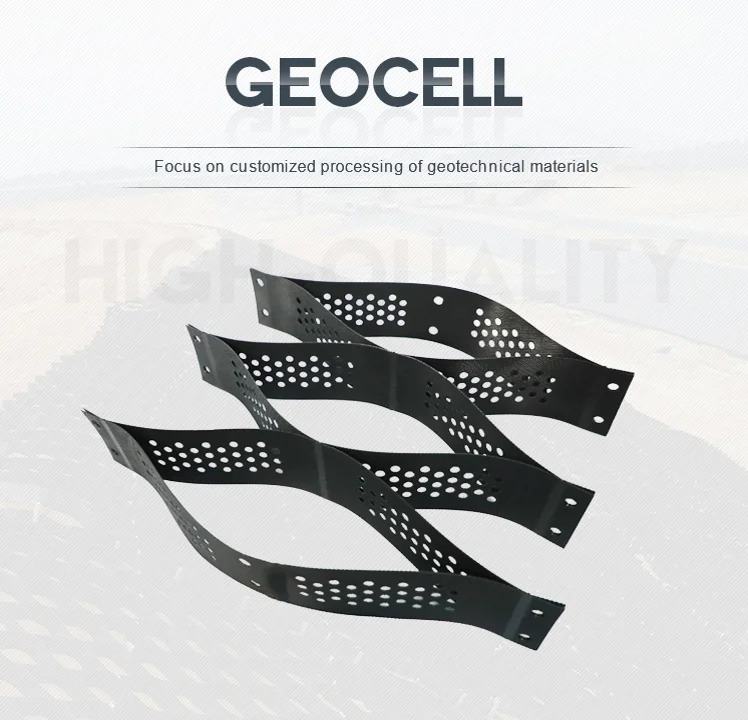

High Quality Grass Grid Pavers Hdpe Geocell

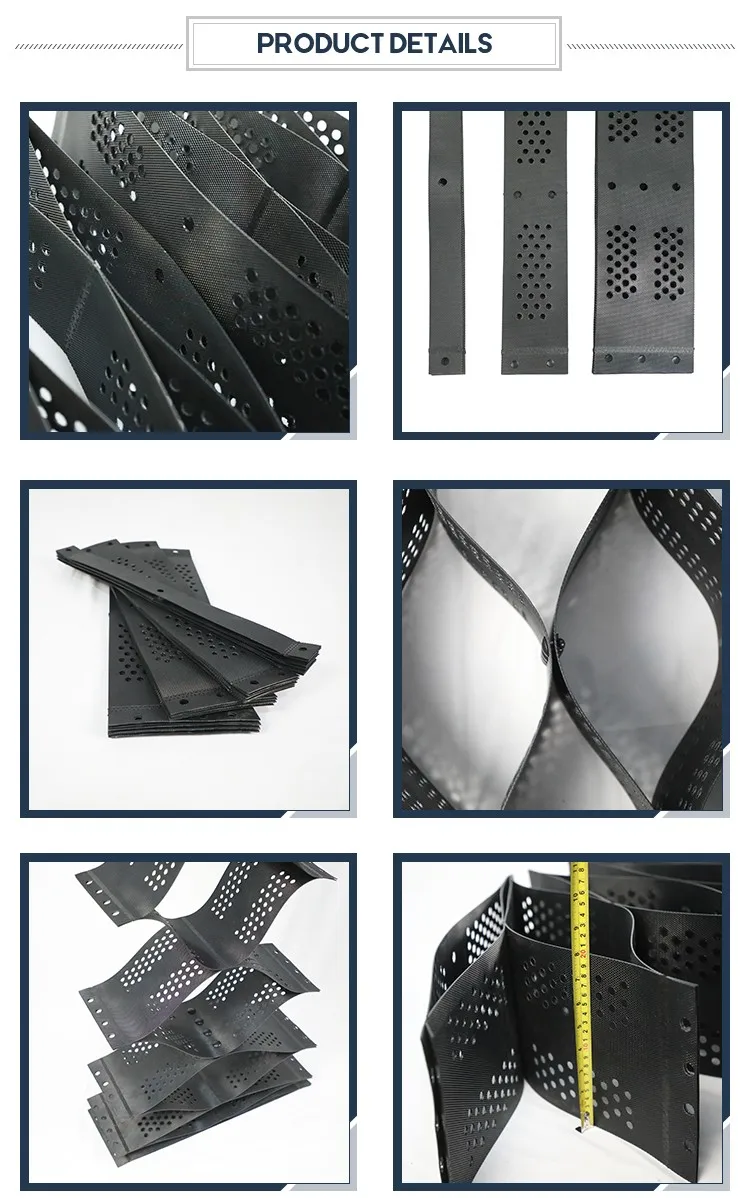

HDPE Geocell is a flexible, three-dimensional honeycomb-like structure manufactured from high-density polyethylene (HDPE) strips that are ultrasonically welded together, forming a strong and durable confinement system. This geocell structure can be expanded on-site and filled with various infill materials such as soil, sand, aggregate, or concrete.

Designed for superior load distribution and stability, HDPE geocells are widely used in:

Unpaved and reinforced road construction

Retaining wall systems

Slope erosion control

Channel protection and stormwater management

Offering high tensile strength, chemical resistance, and excellent flexibility, HDPE geocells are a cost-effective and sustainable solution for civil engineering and environmental protection projects. They ensure rapid deployment and long-term performance even in demanding site conditions.

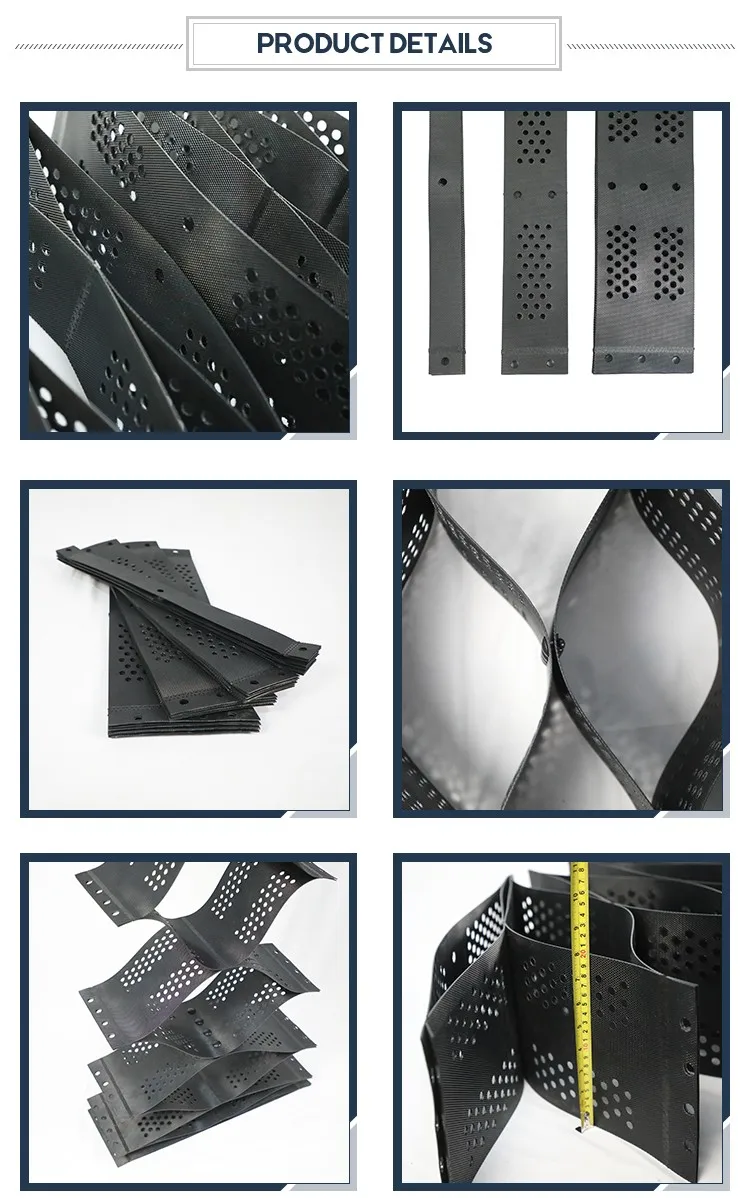

Technical parameter

| Geocell | ||||

| item | PP | PE | ||

| tensile strength of Strip ≥(Mpa) | 23 | 20 | ||

| Tensile strength of weld ≥(N/cm) | 100 | 100 | ||

| Tensile strength of cell edge ≥(N/cm) | 200 | 200 | ||

| Intermediate tensile strength of cell sheet ≥(N/cm) | 120 | 120 | ||

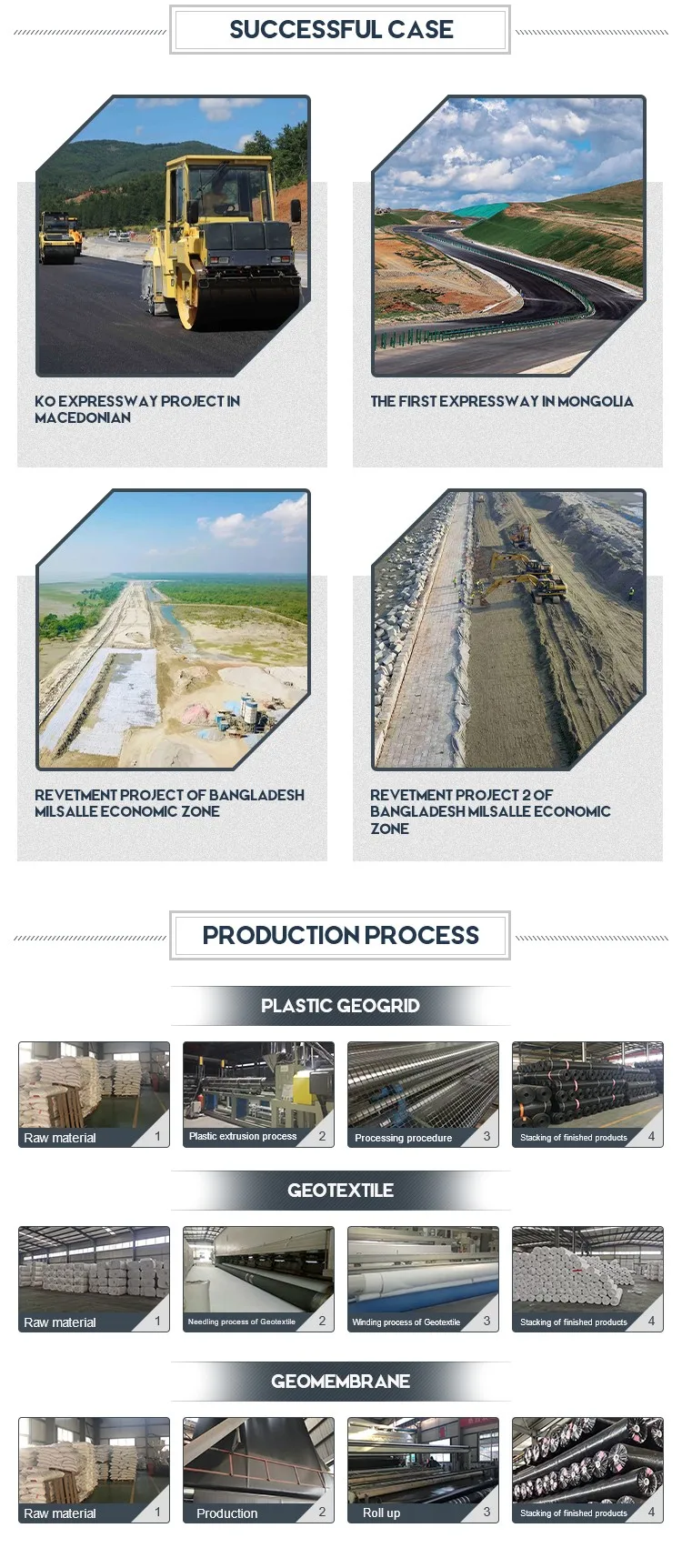

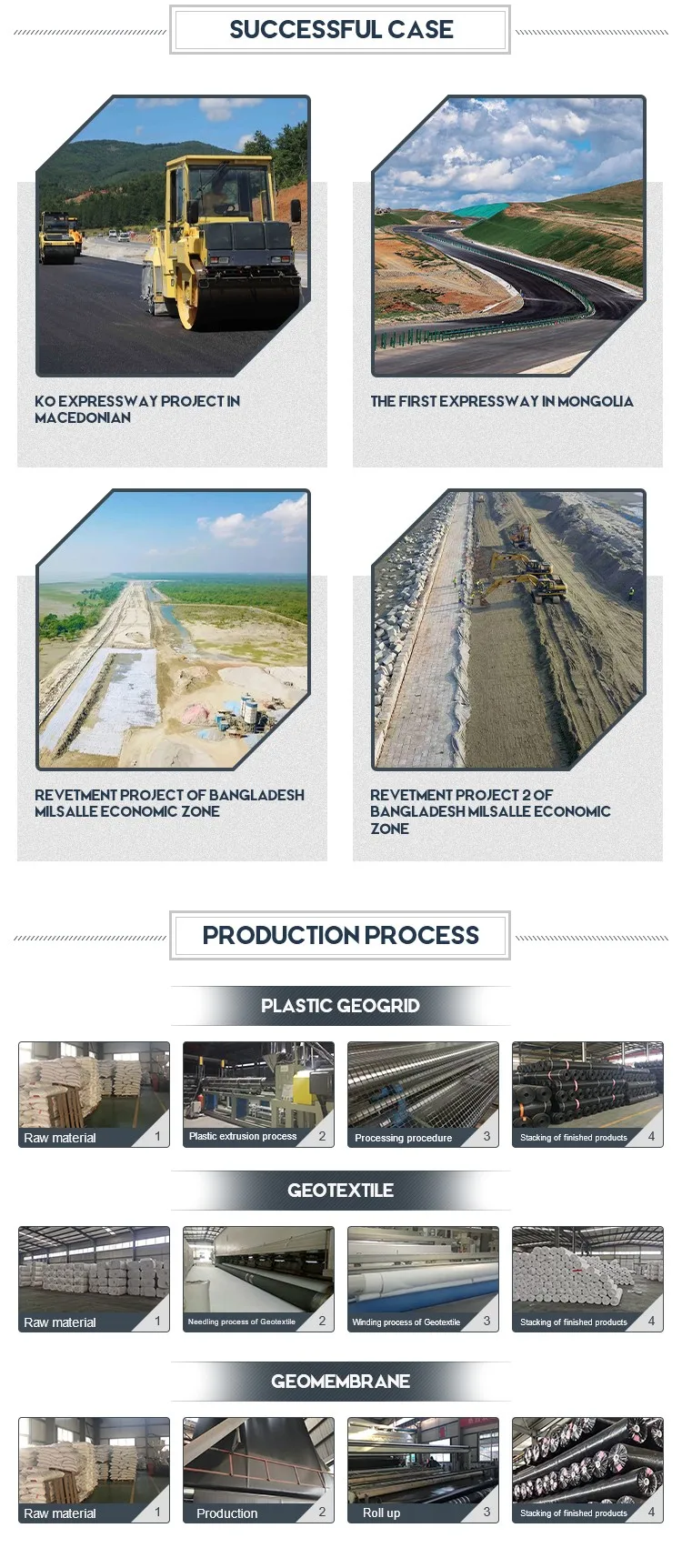

Why GeocellIn roads, rail,wers, slope applications, and similar constructions we sometimes encounter soft and/or weak. The traditional approach is to fill these areas with expensive materials, which can be costly and time-consuming. However, there is an effective alternative method: using geocell directly on the subgrade. Geocell is made of ultrasonically-welded high-density polyethylene (HDPE) and can be expanded to form a honeycomb structure. Cells are then filled with readily available granular materials and compacted. The Geoc solution addresses soil stability problems in various applications through its high-strength network of interconnected cells.

Confinement from adjacent cells provides additional resistance against the loaded cell through passive resistance, while expansion of the infill is restricted by high hoop strength. Compaction is maintainedocell, resulting in-term reinforcement

Slope Pretection

stability of slopes using vegetated topsoil, aggregate or concrete surfacing

Gruound Stabilisation

Cellular Confinement Systems strengthen the aggregate infill, thereby simultaneously enabling the use of poorly graded inferior material for infill as well as reducing the structural support layer thickness.Typical stabilisation applications include reinforcement of base and subbase layers in flexible pavements, including: roads, railway substructure and ballast confinement;working platforms in intermodal ports; airport runways.

FAQ

Q:Can you send samples?

High Quality Grass Grid Pavers Hdpe Geocell

HDPE Geocell is a flexible, three-dimensional honeycomb-like structure manufactured from high-density polyethylene (HDPE) strips that are ultrasonically welded together, forming a strong and durable confinement system. This geocell structure can be expanded on-site and filled with various infill materials such as soil, sand, aggregate, or concrete.

Designed for superior load distribution and stability, HDPE geocells are widely used in:

Unpaved and reinforced road construction

Retaining wall systems

Slope erosion control

Channel protection and stormwater management

Offering high tensile strength, chemical resistance, and excellent flexibility, HDPE geocells are a cost-effective and sustainable solution for civil engineering and environmental protection projects. They ensure rapid deployment and long-term performance even in demanding site conditions.

Technical parameter

| Geocell | ||||

| item | PP | PE | ||

| tensile strength of Strip ≥(Mpa) | 23 | 20 | ||

| Tensile strength of weld ≥(N/cm) | 100 | 100 | ||

| Tensile strength of cell edge ≥(N/cm) | 200 | 200 | ||

| Intermediate tensile strength of cell sheet ≥(N/cm) | 120 | 120 | ||

Why GeocellIn roads, rail,wers, slope applications, and similar constructions we sometimes encounter soft and/or weak. The traditional approach is to fill these areas with expensive materials, which can be costly and time-consuming. However, there is an effective alternative method: using geocell directly on the subgrade. Geocell is made of ultrasonically-welded high-density polyethylene (HDPE) and can be expanded to form a honeycomb structure. Cells are then filled with readily available granular materials and compacted. The Geoc solution addresses soil stability problems in various applications through its high-strength network of interconnected cells.

Confinement from adjacent cells provides additional resistance against the loaded cell through passive resistance, while expansion of the infill is restricted by high hoop strength. Compaction is maintainedocell, resulting in-term reinforcement

Slope Pretection

stability of slopes using vegetated topsoil, aggregate or concrete surfacing

Gruound Stabilisation

Cellular Confinement Systems strengthen the aggregate infill, thereby simultaneously enabling the use of poorly graded inferior material for infill as well as reducing the structural support layer thickness.Typical stabilisation applications include reinforcement of base and subbase layers in flexible pavements, including: roads, railway substructure and ballast confinement;working platforms in intermodal ports; airport runways.

FAQ

Q:Can you send samples?