| Availability: | |

|---|---|

| Quantity: | |

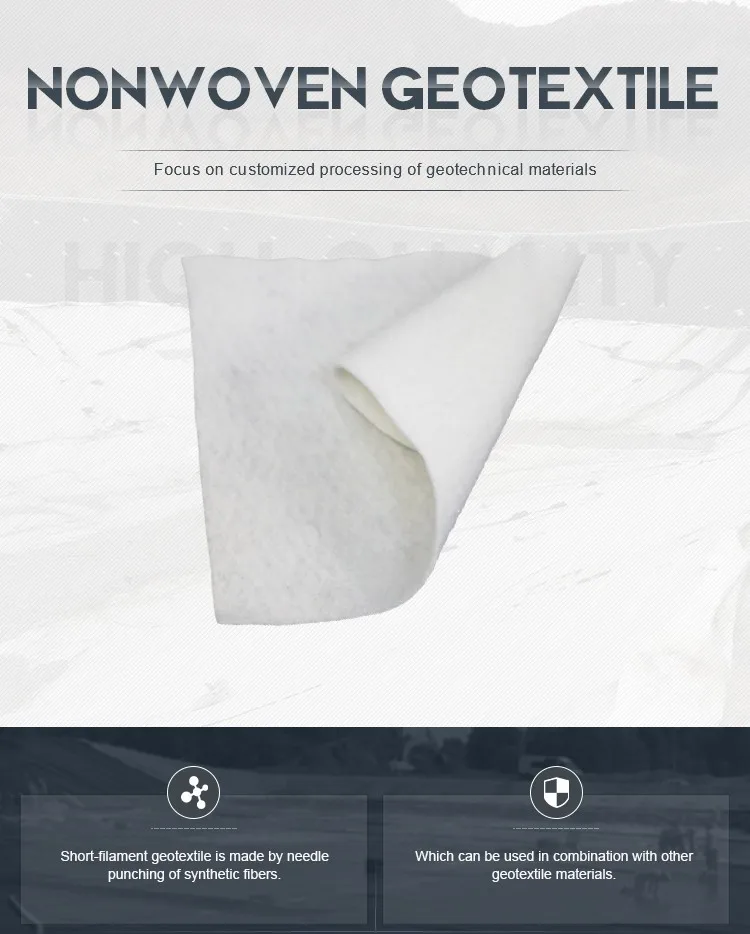

Needle Punched Short Fiber Geotextile 300gsm – Road Base Stabilization And Paving Nonwoven Fabric Material from China Manufacturer - Works of civil, Engineering Products and Solutions | Zhongloo China

1. High strength: due to the plastic fiber, it can keep sufficient strength and elongation in the wet state.

2. Corrosion resistance: it can in different ph value of soil and water corrosion for long.

3. Good permeability: have a gap between the fibre, therefore has the good porous.

4. Good antimicrobial property: do not damaged by microbes and insects.

5. Construction is convenient: because the material is qualitative light, soft, so delivery, laying, construction is convenient.

6. Anti-aging, the product has very high anti-ultraviolet radiation ability, not easy to degradation.

7. High temperature resistance to up to 230℃ maintaining structure stability and original physical properties.

8. High flat drainage and vertical permeability.

Needle punched nonwoven Geotextiles are made of polyester or polypropylene in random directions and punched together by needles. Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation, filtration, reinforcement, protection drainage and maintenance function, etc.

Anti-scouring slope protection

Highway roadbed reinforcement

Agricultural transformation of saline-alkali land

| Staple Fiber Needle Punched Non-woven Geotextile Technical Parameter (GB standard) | |||||||||

| Item | Standard Specification | ||||||||

| Vertical and horizontal fracture strength(KN/M) | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 |

| Elongation corresponding to standard breaking strength (%) | 20-100 | ||||||||

| CBR Bursting strength(KN) | 0.6 | 1 | 1.4 | 1.8 | 2.5 | 3.2 | 4 | 5.5 | 7 |

| Deviation rate of weight per unit area(%) | ±5 | ||||||||

| Vertical and horizontal tearing strength(KN) | 0.10 | 0.15 | 0.20 | 0.25 | 0.40 | 0.50 | 0.65 | 0.80 | 1.00 |

| Width deviation rate(%) | -0.5 | ||||||||

| Thickness deviation rate(%) | ±10 | ||||||||

| Vertical permeability coefficient(cm/s) | k*(0.001-0.1) Ps: k=1.0-9.9 | ||||||||

| Acid and alkali resistance(% ≥) | 80 | ||||||||

| Antioxidant performance(% ≥) | 80 | ||||||||

| UV resistance (% ≥) | 80 | ||||||||

FAQ

Q: Can you send samples?

Needle Punched Short Fiber Geotextile 300gsm – Road Base Stabilization And Paving Nonwoven Fabric Material from China Manufacturer - Works of civil, Engineering Products and Solutions | Zhongloo China

1. High strength: due to the plastic fiber, it can keep sufficient strength and elongation in the wet state.

2. Corrosion resistance: it can in different ph value of soil and water corrosion for long.

3. Good permeability: have a gap between the fibre, therefore has the good porous.

4. Good antimicrobial property: do not damaged by microbes and insects.

5. Construction is convenient: because the material is qualitative light, soft, so delivery, laying, construction is convenient.

6. Anti-aging, the product has very high anti-ultraviolet radiation ability, not easy to degradation.

7. High temperature resistance to up to 230℃ maintaining structure stability and original physical properties.

8. High flat drainage and vertical permeability.

Needle punched nonwoven Geotextiles are made of polyester or polypropylene in random directions and punched together by needles. Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation, filtration, reinforcement, protection drainage and maintenance function, etc.

Anti-scouring slope protection

Highway roadbed reinforcement

Agricultural transformation of saline-alkali land

| Staple Fiber Needle Punched Non-woven Geotextile Technical Parameter (GB standard) | |||||||||

| Item | Standard Specification | ||||||||

| Vertical and horizontal fracture strength(KN/M) | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 |

| Elongation corresponding to standard breaking strength (%) | 20-100 | ||||||||

| CBR Bursting strength(KN) | 0.6 | 1 | 1.4 | 1.8 | 2.5 | 3.2 | 4 | 5.5 | 7 |

| Deviation rate of weight per unit area(%) | ±5 | ||||||||

| Vertical and horizontal tearing strength(KN) | 0.10 | 0.15 | 0.20 | 0.25 | 0.40 | 0.50 | 0.65 | 0.80 | 1.00 |

| Width deviation rate(%) | -0.5 | ||||||||

| Thickness deviation rate(%) | ±10 | ||||||||

| Vertical permeability coefficient(cm/s) | k*(0.001-0.1) Ps: k=1.0-9.9 | ||||||||

| Acid and alkali resistance(% ≥) | 80 | ||||||||

| Antioxidant performance(% ≥) | 80 | ||||||||

| UV resistance (% ≥) | 80 | ||||||||

FAQ

Q: Can you send samples?