| Standard: | |

|---|---|

| Width: | |

| Raw material : | |

| Availability: | |

| Quantity: | |

ZL-TGGS

zhongloo

PP Uniaxial Geogrid Soil Erosion Grid Plastic Geogrid with High Tensile Strength

High Strength Polyester Polypropylene Uniaxial Geogrid for Driveway Basement

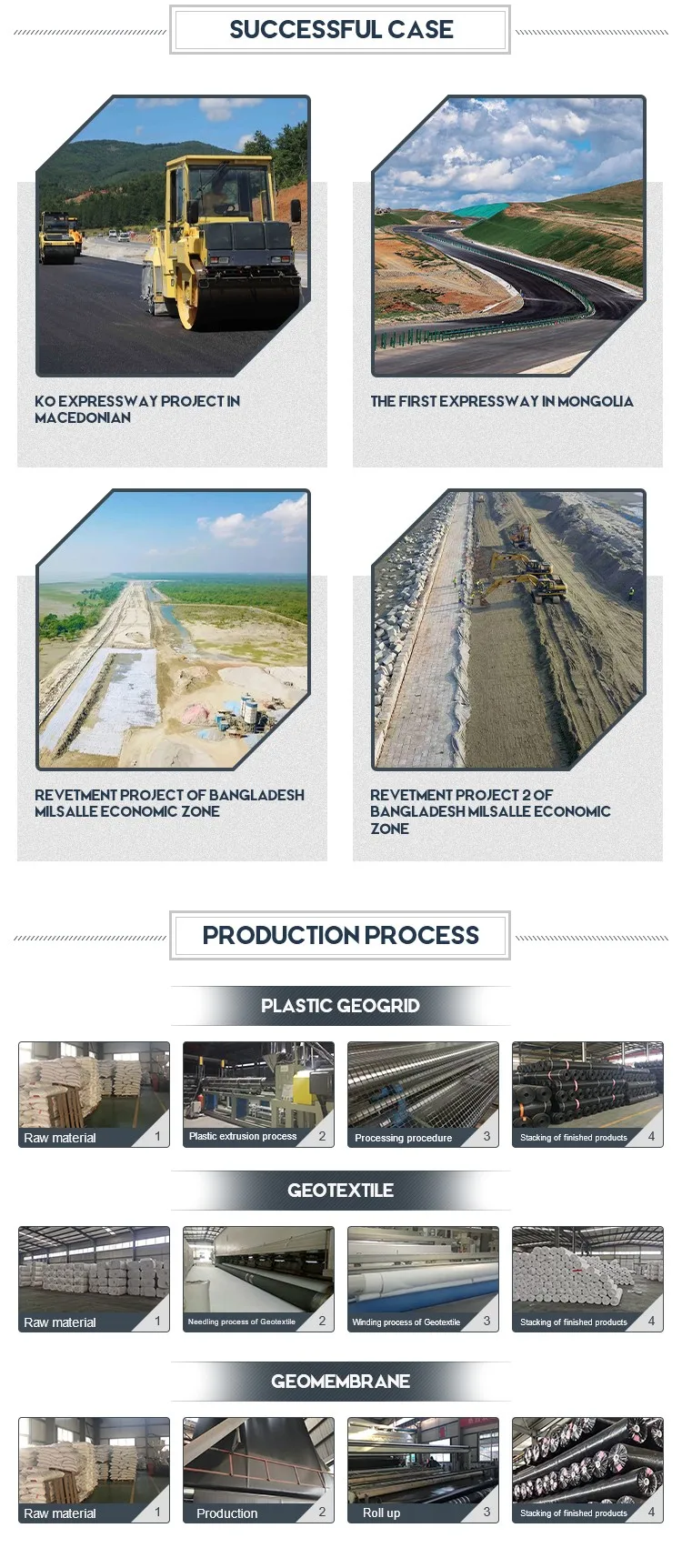

Uniaxially stretched geogrid is a high-strength geosynthetic material designed primarily for soil reinforcement and earth retention applications. It is manufactured using high molecular weight polymers as the base material, combined with anti-UV and anti-aging additives to enhance durability. The production process begins with melt extrusion, forming the polymer into thin sheets. These sheets are then perforated using precision punching equipment to create a regular grid-like aperture structure. Finally, the material undergoes uniaxial stretching in the longitudinal direction, during which the polymer chains are realigned and oriented, significantly improving the tensile strength and structural integrity of the geogrid.

Uniaxially stretched geogrid is a high-strength geosynthetic material designed primarily for soil reinforcement and earth retention applications. It is manufactured using high molecular weight polymers as the base material, combined with anti-UV and anti-aging additives to enhance durability. The production process begins with melt extrusion, forming the polymer into thin sheets. These sheets are then perforated using precision punching equipment to create a regular grid-like aperture structure. Finally, the material undergoes uniaxial stretching in the longitudinal direction, during which the polymer chains are realigned and oriented, significantly improving the tensile strength and structural integrity of the geogrid.

Why Geogrid

Geogrids are essential in modern civil engineering due to their ability to enhance foundation bearing capacity, reinforce slopes, extend pavement life, and improve overall drainage performance. By increasing project stability, minimizing settlement, and reducing material usage, geogrids effectively lower construction costs and improve long-term durability. These benefits make geogrids widely used in infrastructure projects such as highways, railways, slope stabilization, and airport runways.

Geogrids function by reinforcing soil structures and improving load distribution. They enhance the bearing capacity of weak foundations, reduce differential settlement, and provide tensile reinforcement to subgrades and roadbeds, effectively preventing cracking and increasing structural longevity. In slope protection and retaining wall applications, geogrids increase soil shear strength, reduce the risk of landslides, and improve overall safety. Their open-grid design promotes drainage, reduces soil erosion, and supports the stability of embankments. By reducing the required fill volume and improving construction efficiency, geogrids offer a cost-effective solution for a wide range of civil engineering applications.

Geogrids Details

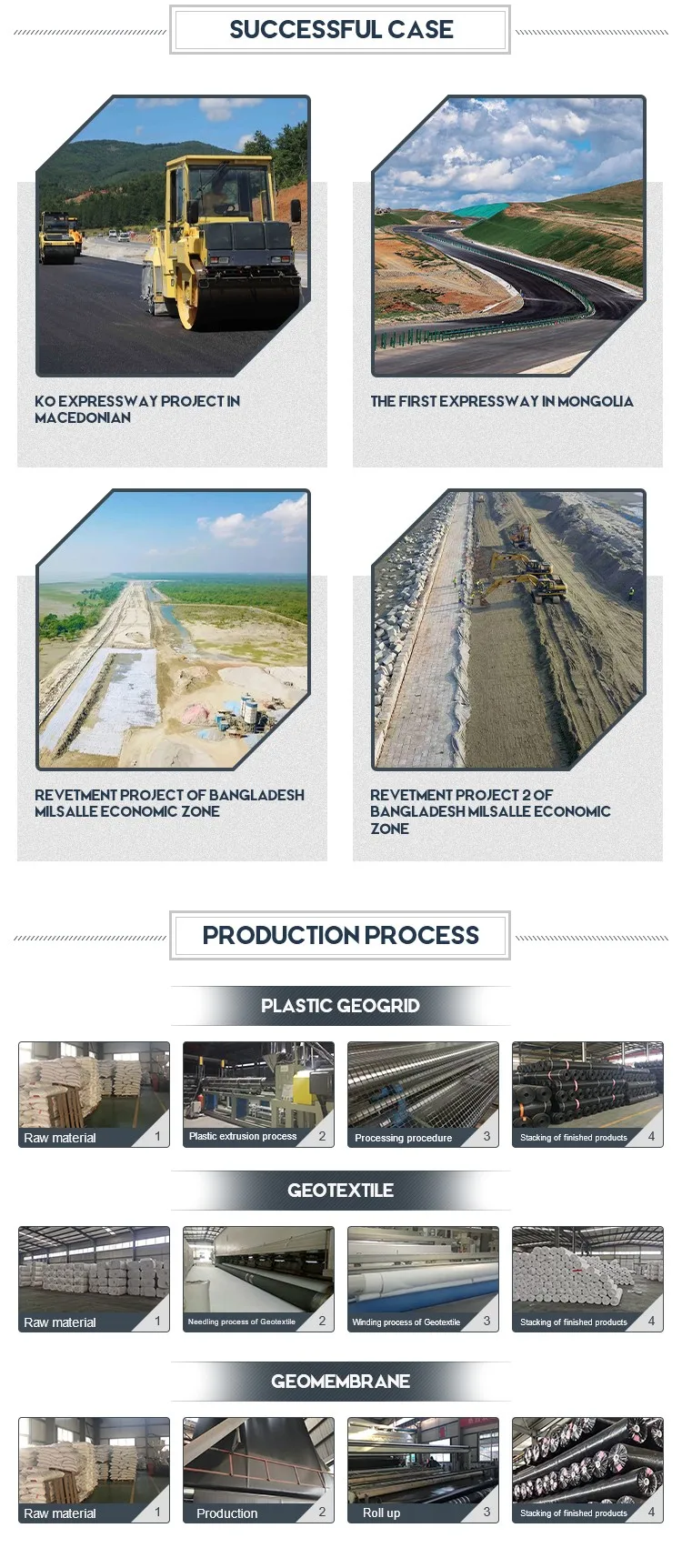

Project Examples

Retaining Wall

Used to reinforce weak foundations: Geogrids can quickly improve the bearing capacity of the foundation and control the development of settlement. The lateral constraint of the roadbed can effectively disperse the load onto a wider roadbed.

Slope Pretection

Strengthening embankment slopes and retaining walls: Strengthening embankment slopes or retaining walls with geogrids can reduce land occupation by half, extend service life, and reduce costs by 20% to 50%.

Gruound Stabilisation

Unidirectional plastic geogrid is used for reinforcement of asphalt or cement pavement: geogrid is laid at the bottom of asphalt or cement pavement, which can reduce the depth of ruts, extend the fatigue life of the pavement, and also reduce the thickness of asphalt or cement pavement to save costs

Load Support

Load Support

For landfill sites: The combination of geogrids and other geosynthetic materials can effectively solve the problems of uneven

foundation settlement and uneven emissions of derived gases, and maximize the utilization of landfill storage capacity.

FAQ

Q:Can you send samples?

PP Uniaxial Geogrid Soil Erosion Grid Plastic Geogrid with High Tensile Strength

High Strength Polyester Polypropylene Uniaxial Geogrid for Driveway Basement

Uniaxially stretched geogrid is a high-strength geosynthetic material designed primarily for soil reinforcement and earth retention applications. It is manufactured using high molecular weight polymers as the base material, combined with anti-UV and anti-aging additives to enhance durability. The production process begins with melt extrusion, forming the polymer into thin sheets. These sheets are then perforated using precision punching equipment to create a regular grid-like aperture structure. Finally, the material undergoes uniaxial stretching in the longitudinal direction, during which the polymer chains are realigned and oriented, significantly improving the tensile strength and structural integrity of the geogrid.

Uniaxially stretched geogrid is a high-strength geosynthetic material designed primarily for soil reinforcement and earth retention applications. It is manufactured using high molecular weight polymers as the base material, combined with anti-UV and anti-aging additives to enhance durability. The production process begins with melt extrusion, forming the polymer into thin sheets. These sheets are then perforated using precision punching equipment to create a regular grid-like aperture structure. Finally, the material undergoes uniaxial stretching in the longitudinal direction, during which the polymer chains are realigned and oriented, significantly improving the tensile strength and structural integrity of the geogrid.

Why Geogrid

Geogrids are essential in modern civil engineering due to their ability to enhance foundation bearing capacity, reinforce slopes, extend pavement life, and improve overall drainage performance. By increasing project stability, minimizing settlement, and reducing material usage, geogrids effectively lower construction costs and improve long-term durability. These benefits make geogrids widely used in infrastructure projects such as highways, railways, slope stabilization, and airport runways.

Geogrids function by reinforcing soil structures and improving load distribution. They enhance the bearing capacity of weak foundations, reduce differential settlement, and provide tensile reinforcement to subgrades and roadbeds, effectively preventing cracking and increasing structural longevity. In slope protection and retaining wall applications, geogrids increase soil shear strength, reduce the risk of landslides, and improve overall safety. Their open-grid design promotes drainage, reduces soil erosion, and supports the stability of embankments. By reducing the required fill volume and improving construction efficiency, geogrids offer a cost-effective solution for a wide range of civil engineering applications.

Geogrids Details

Project Examples

Retaining Wall

Used to reinforce weak foundations: Geogrids can quickly improve the bearing capacity of the foundation and control the development of settlement. The lateral constraint of the roadbed can effectively disperse the load onto a wider roadbed.

Slope Pretection

Strengthening embankment slopes and retaining walls: Strengthening embankment slopes or retaining walls with geogrids can reduce land occupation by half, extend service life, and reduce costs by 20% to 50%.

Gruound Stabilisation

Unidirectional plastic geogrid is used for reinforcement of asphalt or cement pavement: geogrid is laid at the bottom of asphalt or cement pavement, which can reduce the depth of ruts, extend the fatigue life of the pavement, and also reduce the thickness of asphalt or cement pavement to save costs

Load Support

Load Support

For landfill sites: The combination of geogrids and other geosynthetic materials can effectively solve the problems of uneven

foundation settlement and uneven emissions of derived gases, and maximize the utilization of landfill storage capacity.

FAQ

Q:Can you send samples?