| Raw material : | |

|---|---|

| Length: | |

| width: | |

| Color: | |

| Availability: | |

| Quantity: | |

ZL-TGB-CS

zhongloo

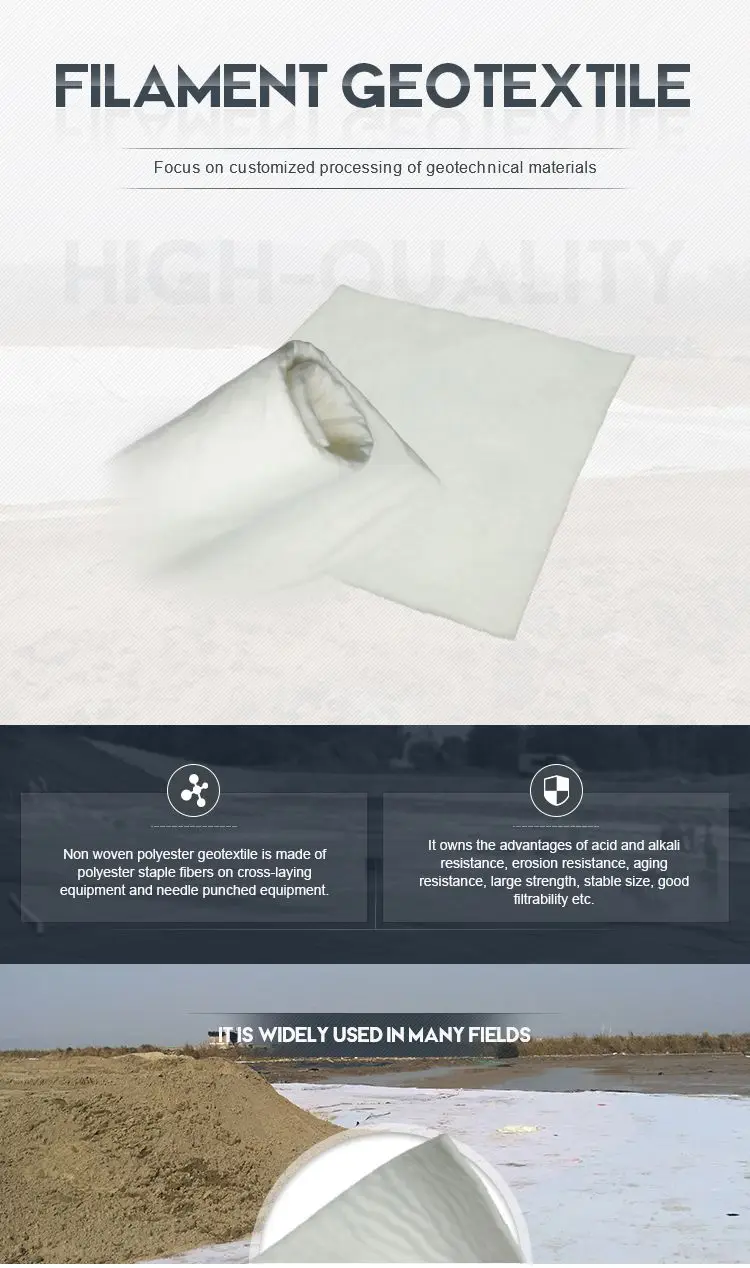

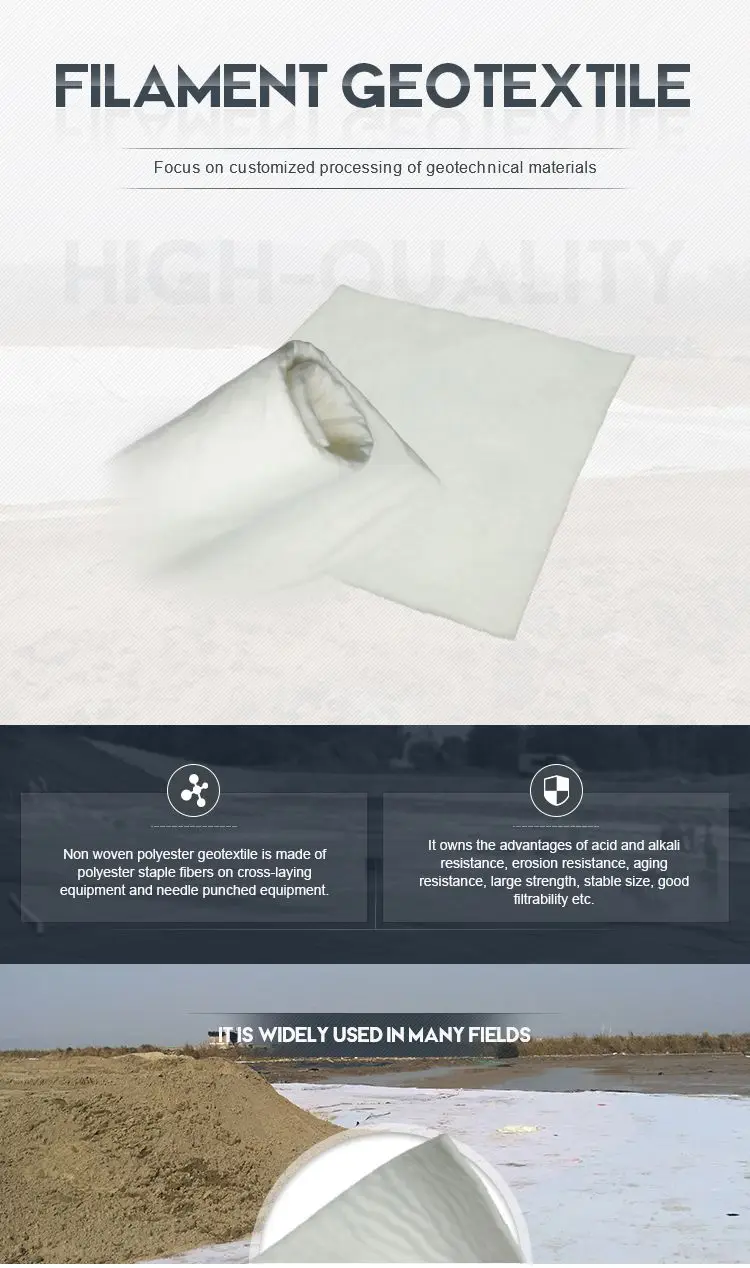

Polypropylene/Polyester Non-Woven Geotextile Fabric – High-Strength Filtration and Stabilization Material for Road Construction Projects

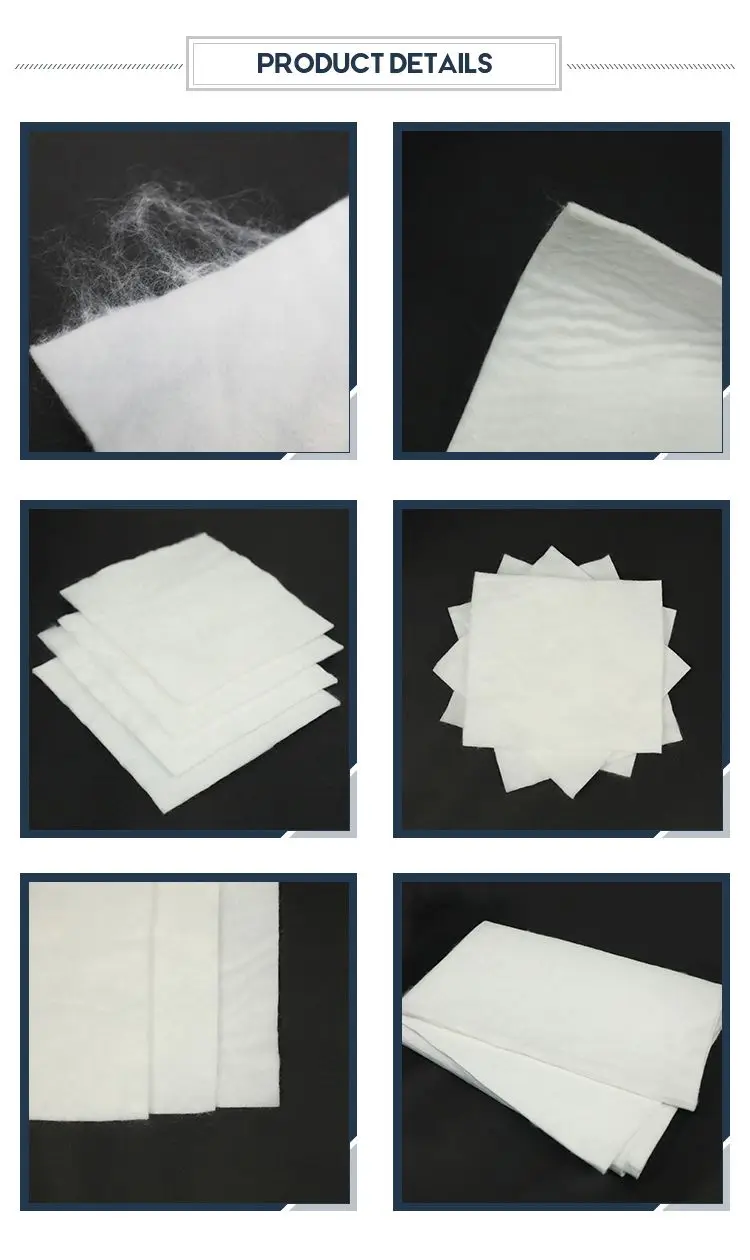

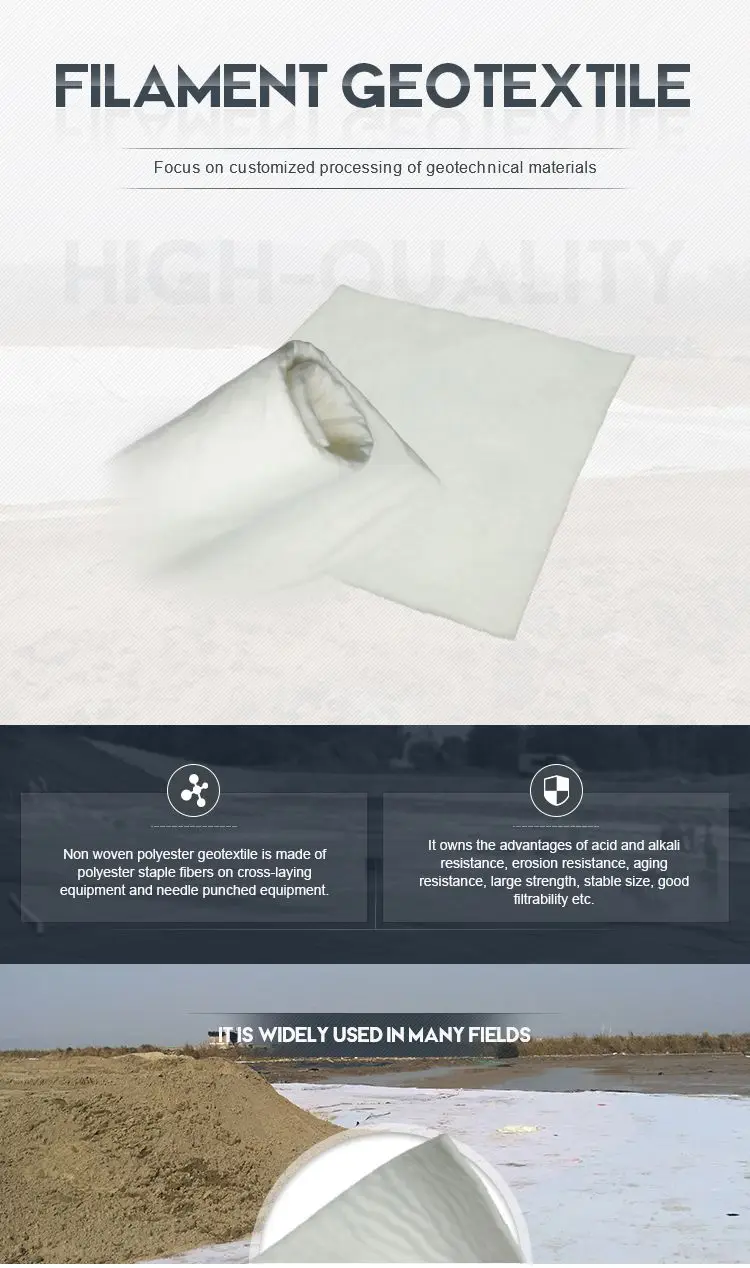

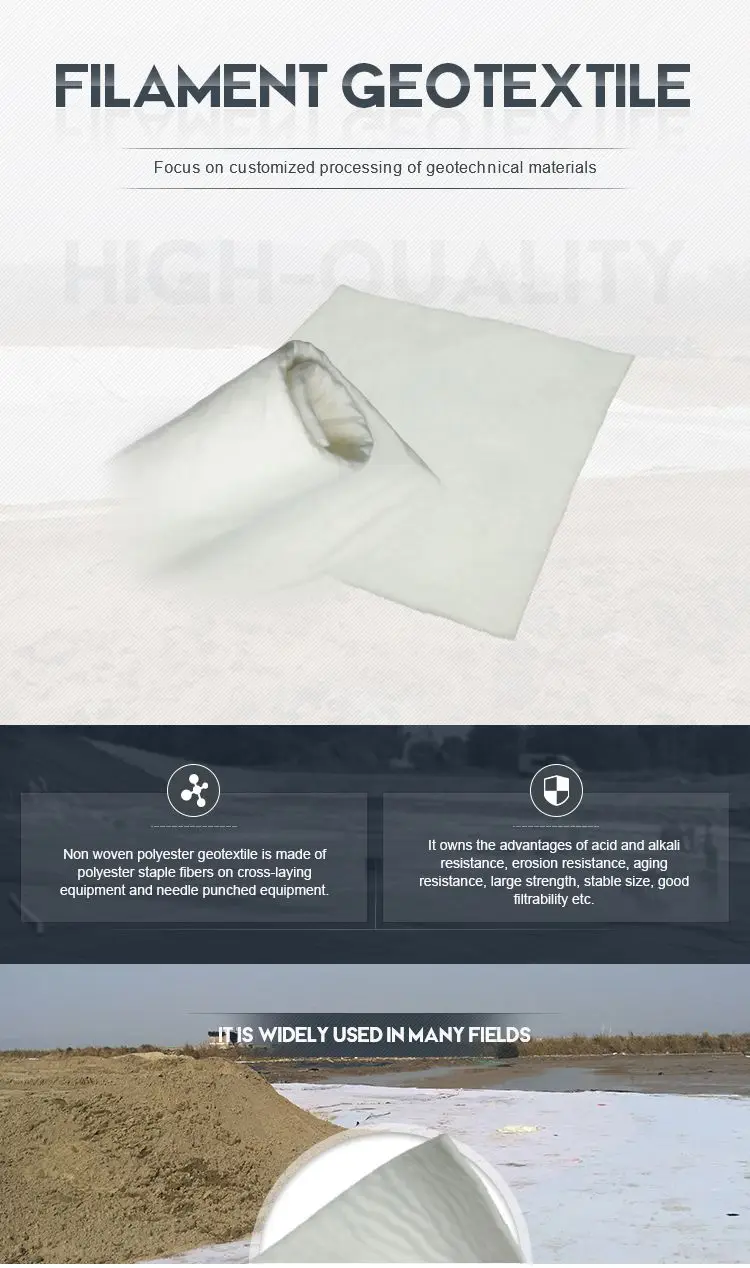

Filament Fiber Nonwoven Geotextile, also known as continuous filament geotextile, is manufactured by the process of needle punching using high-quality polyester (PET) or polypropylene (PP) virgin chips. The continuous filaments are entangled together to form a robust, dimensionally stable, and permeable fabric.

This geotextile offers excellent mechanical properties, including high tensile strength, low elongation, and superior resistance to UV radiation, chemical corrosion, and biological degradation. It ensures effective filtration, separation, reinforcement, and drainage functions in various geotechnical and civil engineering applications.

Widely used in road construction, railway foundations, landfills, tunnel protection, slope reinforcement, and water conservancy projects, long fiber geotextile enhances soil stability, extends project lifespan, and reduces maintenance costs.

1.High Strength – Superior tensile strength in all directions compared to other needle-punched nonwoven fabrics of the same weight.

2.UV Resistance – Highly resistant to ultraviolet light, ensuring long-term durability. 3.Extreme Temperature Resistance – Withstands temperatures up to 230°C while maintaining structural integrity.

6.Ductility – Excellent elongation under stress, adapting to uneven and irregular substrates.

| Non-woven Geotextile Technical Parameter (GB standard) | |||||||||

| Item | unit | Standard Specification | |||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | ||

| Thickness≥ | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 |

| width Deciation | % | 0.5 | |||||||

| Breaking strength | KN/M | 2.50 | 4.50 | 6.50 | 8.00 | 9.50 | 11.00 | 12.50 | 14.00 |

| Breaking Elongation | % | 25-100 | |||||||

| Weight Tolerance | g/m² | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 |

| CBR Tear Strength≥ | KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 |

| Tear Strength≥ | KN | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 |

| Vertical Permeability | N/5cm | Kx(10﹣¹-10﹣³) | |||||||

| EOS 090 | mm | 0.07-0.2 | |||||||

Railway subgrade drainage

Railway subgrade drainage

Highway roadbed reinforcement

Agricultural transformation of saline-alkali land

Q:Can you send samples? A:Yes,we are very happy to provide you with free samples to check the quality of our products.

Polypropylene/Polyester Non-Woven Geotextile Fabric – High-Strength Filtration and Stabilization Material for Road Construction Projects

Filament Fiber Nonwoven Geotextile, also known as continuous filament geotextile, is manufactured by the process of needle punching using high-quality polyester (PET) or polypropylene (PP) virgin chips. The continuous filaments are entangled together to form a robust, dimensionally stable, and permeable fabric.

This geotextile offers excellent mechanical properties, including high tensile strength, low elongation, and superior resistance to UV radiation, chemical corrosion, and biological degradation. It ensures effective filtration, separation, reinforcement, and drainage functions in various geotechnical and civil engineering applications.

Widely used in road construction, railway foundations, landfills, tunnel protection, slope reinforcement, and water conservancy projects, long fiber geotextile enhances soil stability, extends project lifespan, and reduces maintenance costs.

1.High Strength – Superior tensile strength in all directions compared to other needle-punched nonwoven fabrics of the same weight.

2.UV Resistance – Highly resistant to ultraviolet light, ensuring long-term durability. 3.Extreme Temperature Resistance – Withstands temperatures up to 230°C while maintaining structural integrity.

6.Ductility – Excellent elongation under stress, adapting to uneven and irregular substrates.

| Non-woven Geotextile Technical Parameter (GB standard) | |||||||||

| Item | unit | Standard Specification | |||||||

| 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | ||

| Thickness≥ | mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 |

| width Deciation | % | 0.5 | |||||||

| Breaking strength | KN/M | 2.50 | 4.50 | 6.50 | 8.00 | 9.50 | 11.00 | 12.50 | 14.00 |

| Breaking Elongation | % | 25-100 | |||||||

| Weight Tolerance | g/m² | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 |

| CBR Tear Strength≥ | KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 |

| Tear Strength≥ | KN | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 |

| Vertical Permeability | N/5cm | Kx(10﹣¹-10﹣³) | |||||||

| EOS 090 | mm | 0.07-0.2 | |||||||

Railway subgrade drainage

Railway subgrade drainage

Highway roadbed reinforcement

Agricultural transformation of saline-alkali land

Q:Can you send samples? A:Yes,we are very happy to provide you with free samples to check the quality of our products.