| Color: | |

|---|---|

| Material: | |

| Length: | |

| Certificate: | |

| width: | |

| Availability: | |

| Quantity: | |

ZL-TGM

zhongloo

1mm 2mm HDPE LDPE LLDPE GM13 Geomembrane Fish Farm Landfill Pond Liner Waterproof Geomembrane

Geomembrane: Durable, Impermeable Synthetic Membrane for Fluid Containment

Geomembranes are highly impermeable synthetic membranes primarily manufactured from polyethylene (PE), polyvinyl chloride (PVC), or other polymer resins. Widely utilized in engineering and environmental projects, they serve as effective barriers to prevent fluid seepage and contamination.

Key Features:

Excellent chemical resistance, tolerating acids, alkalis, and organic solvents

Stable performance under extreme temperatures and harsh environmental conditions

High tensile strength, elongation at break, and puncture resistance for long-term durability

Flexible and easy to install, commonly joined by welding or adhesive bonding to form continuous impermeable layers

Common Applications:

Landfills for hazardous waste containment

Water reservoirs and irrigation canals to prevent leakage and conserve water

Mining sites for isolation of toxic liquids

Wastewater treatment facilities and environmental protection projects

Additional Benefits:

Lightweight design reduces transportation and installation costs

Customizable thickness, size, and material composition to meet specific project needs

Manufactured under strict quality control and certified to international standards such as ASTM and ISO

Geomembranes provide reliable protection for soil and water resources, ensuring environmental safety and supporting sustainable infrastructure development.

1.High Impermeability for Effective Containment Geomembranes offer exceptional fluid resistance, forming a near-impermeable barrier that prevents leakage of water, chemicals, or hazardous substances. This makes them ideal for critical applications like landfill liners, reservoir waterproofing, and industrial wastewater ponds, where containment reliability is non-negotiable.

2.Superior Chemical & Environmental Resistance Constructed from durable polymers (e.g., HDPE, LLDPE, PVC), geomembranes withstand corrosion from acids, alkalis, solvents, and petroleum products. They also resist UV degradation, extreme temperatures (-70°C to +110°C), and microbial attack, ensuring long-term performance in harsh environments without material breakdown.

3.High Tensile Strength & Durability Engineered to endure mechanical stress, geomembranes feature high tensile strength (up to 50 MPa) and elongation at break (often >300%), resisting punctures, tears, and soil settlement. This durability minimizes maintenance needs and extends project lifespans—ideal for infrastructure requiring decades of reliable service.

4.Versatile Application Across Industries Environmental Protection: Landfill liners, hazardous waste containment, contaminated site remediation. Water Management: Reservoirs, dams, irrigation canals, stormwater retention ponds. Energy & Mining: Tailings ponds, oil & gas seepage control, brine storage. Agriculture: Pond liners, water storage for drought-prone regions. Civil Engineering: Canal liners, basement waterproofing, landfill caps.

5.Easy Installation & Cost Efficiency Lightweight and flexible, geomembranes are easy to transport, handle, and install. They can be welded on-site using hot air, extrusion, or fusion techniques to form seamless, large-area liners, reducing labor costs and installation time. Their thin profile (0.2mm–3mm) also minimizes material usage compared to traditional concrete or clay liners.

6.Customizable & Adaptable Design Available in various thicknesses, widths, and material compositions, geomembranes can be tailored to project needs: HDPE geomembranes for high chemical resistance in landfills. LLDPE for flexibility in irregular terrains. PVC for cost-effective water retention projects. Custom coatings or reinforcements (e.g., geotextile composites) can enhance performance for specific challenges.

7.Eco-Friendly & Sustainable Solution Many geomembranes use recyclable polymers, and their long lifespan reduces the need for frequent replacements, minimizing environmental impact. In green projects, they enable water conservation in agriculture and protect ecosystems by preventing soil and groundwater contamination.

8.Compliance with International Standards Manufactured to strict norms (ASTM D3767, ISO 13954, GB/T 17643), geomembranes undergo rigorous testing for permeability, tensile strength, and weathering resistance. Third-party certifications ensure consistency and reliability for global projects.

9.Cost Savings Through Long-Term Performance While initial costs may be higher than traditional liners, geomembranes offer significant lifecycle savings: their durability reduces repair, replacement, and maintenance expenses, making them a cost-effective choice for long-term infrastructure.

10.Seamless Integration with Geosynthetic Systems Geomembranes can be combined with geotextiles, geogrids, or geocomposites to form multi-layer systems, enhancing stability, filtration, and protection—ideal for complex projects like landfill capping or slope stabilization.

BASIC DETAILS

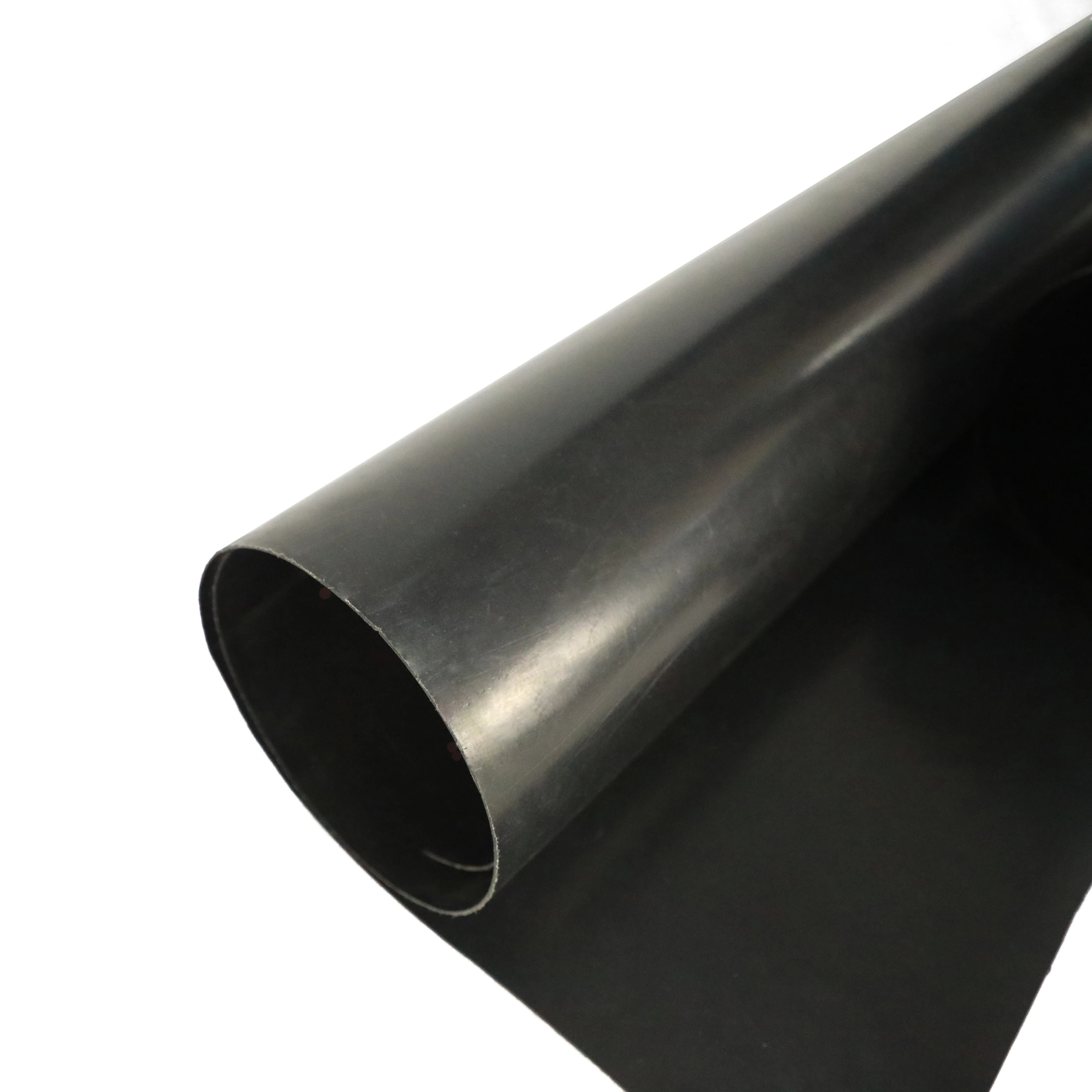

Product Name: Geomembrane / Pond Liner

Available Thickness: 0.1mm, 0.2mm, 0.3mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm

Available Width: 4m, 5m, 5.8m, 6.0m, 7m, 8m, 10m

Standard Length: 50m / 100m per roll

Color Options: Black, White, Blue, Green

Surface Type: Smooth or Textured

Material Options: HDPE, LDPE, LLDPE

Certifications: ISO, TUV, SGS

Quality Control: Third-party testing and in-house laboratory inspection

Our high-density polyethylene (HDPE) geomembranes serve as an effective impermeable barrier against a wide range of liquids and solids. They feature outstanding chemical resistance, UV resistance, excellent impermeability, and high tensile and welded seam strength. These properties make them ideal for use as lining materials in various applications.

Available in a wide range of thicknesses and prices depending on model specifications, our geomembranes are produced with the following capacity:

Thickness: 0.2 mm to 5 mm

Width: 1 meter to 12 meters

They are especially suitable for seepage control in demanding environments and are widely used in aquaculture, water reservoirs, sewage treatment ponds, and other water containment or environmental protection projects.

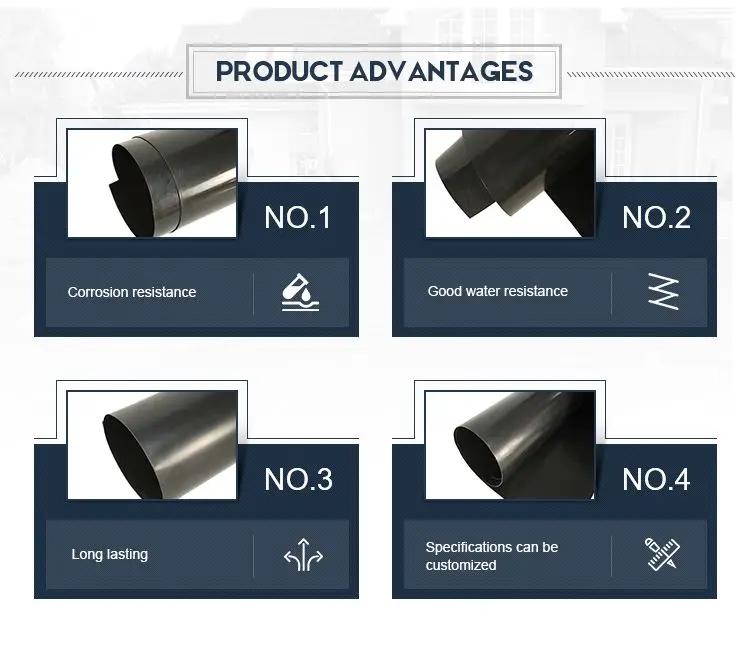

Product Advantages

HDPE Geomembrane Applications

1. Aquaculture

HDPE geomembrane provides excellent anti-seepage performance, making it ideal for use in aquaculture environments such as fish ponds, shrimp ponds, and water tanks. It helps maintain water quality, reduces maintenance costs, and improves yield.

2. Landfills

HDPE geomembrane is the most widely used impermeable material in landfill engineering. It is commonly applied in landfill base liners, capping covers, and leachate collection ponds to prevent environmental contamination and groundwater pollution.

3. Water Treatment Systems

In water treatment and power plants, HDPE geomembrane is used to line adjustment tanks, sewage treatment ponds, and other components of water management systems, providing reliable containment and leak prevention.

4. Mining

In mining operations, HDPE geomembrane is used for heap leach pads, pregnant solution ponds, evaporation ponds, tailings containment, and other critical applications. It offers excellent chemical resistance and long-term durability in harsh mining environments.

Product Example

Product Specification

HDPE Geomembrane pond liner Technical Parameter

ASTM Standard geomembrane

| Spec Properties | Test method ASTM | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

| Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm |

| Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

| Tensile Properties (Each direction) (≥) • yield strength • break strength • yield elongation • break elongation | D 6693 Type IV | 8 kN/m 14kN/m 12% 700% | 11 kN/m 20kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 18 kN/m 33 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

| Tear Resistance (≥) | D 1004 | 64 N | 93 N | 125 N | 156 N | 187 N | 249 N | 311 N |

| Puncture Resistance (≥) | D 4833 | 160 N | 240 N | 320 N | 400 N | 480 N | 640 N | 800 N |

| Stress Crack Resistance (≥) | D 5397 | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. |

| Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

| Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

| Oxidative Induction Time (OIT) (≥) (a)Standard OIT - or - (b)High Pressure OIT | D 3895 D 5885 | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. |

FAQ

Q:Can you send samples?

A:Yes,we are very happy to provide you with free samples to check the quality of our products.

Q:Are you a manufacturer or a trading company?

A:Our company located in Hefei,Anhui Province,with are gistered capital of 52 miion yuan.It is a professiona lmanufacturer of geomembrane,geotextile,geogrid and other products.So we have the competitive price with best quality.

Q:Can you produce the product according to customers' requirements?

A:Sure,we are professional manufacturer,OEM and ODM are both welcome.

Q:How long is the delivery time?

A:General within 3-7days after received the deposit

Q:How to control product quality?

A:Our factory adopts lean management,products from the beginning to the end of the production process have strict quality control.All products must be strictly tested before packing and shipping

1mm 2mm HDPE LDPE LLDPE GM13 Geomembrane Fish Farm Landfill Pond Liner Waterproof Geomembrane

Geomembrane: Durable, Impermeable Synthetic Membrane for Fluid Containment

Geomembranes are highly impermeable synthetic membranes primarily manufactured from polyethylene (PE), polyvinyl chloride (PVC), or other polymer resins. Widely utilized in engineering and environmental projects, they serve as effective barriers to prevent fluid seepage and contamination.

Key Features:

Excellent chemical resistance, tolerating acids, alkalis, and organic solvents

Stable performance under extreme temperatures and harsh environmental conditions

High tensile strength, elongation at break, and puncture resistance for long-term durability

Flexible and easy to install, commonly joined by welding or adhesive bonding to form continuous impermeable layers

Common Applications:

Landfills for hazardous waste containment

Water reservoirs and irrigation canals to prevent leakage and conserve water

Mining sites for isolation of toxic liquids

Wastewater treatment facilities and environmental protection projects

Additional Benefits:

Lightweight design reduces transportation and installation costs

Customizable thickness, size, and material composition to meet specific project needs

Manufactured under strict quality control and certified to international standards such as ASTM and ISO

Geomembranes provide reliable protection for soil and water resources, ensuring environmental safety and supporting sustainable infrastructure development.

1.High Impermeability for Effective Containment Geomembranes offer exceptional fluid resistance, forming a near-impermeable barrier that prevents leakage of water, chemicals, or hazardous substances. This makes them ideal for critical applications like landfill liners, reservoir waterproofing, and industrial wastewater ponds, where containment reliability is non-negotiable.

2.Superior Chemical & Environmental Resistance Constructed from durable polymers (e.g., HDPE, LLDPE, PVC), geomembranes withstand corrosion from acids, alkalis, solvents, and petroleum products. They also resist UV degradation, extreme temperatures (-70°C to +110°C), and microbial attack, ensuring long-term performance in harsh environments without material breakdown.

3.High Tensile Strength & Durability Engineered to endure mechanical stress, geomembranes feature high tensile strength (up to 50 MPa) and elongation at break (often >300%), resisting punctures, tears, and soil settlement. This durability minimizes maintenance needs and extends project lifespans—ideal for infrastructure requiring decades of reliable service.

4.Versatile Application Across Industries Environmental Protection: Landfill liners, hazardous waste containment, contaminated site remediation. Water Management: Reservoirs, dams, irrigation canals, stormwater retention ponds. Energy & Mining: Tailings ponds, oil & gas seepage control, brine storage. Agriculture: Pond liners, water storage for drought-prone regions. Civil Engineering: Canal liners, basement waterproofing, landfill caps.

5.Easy Installation & Cost Efficiency Lightweight and flexible, geomembranes are easy to transport, handle, and install. They can be welded on-site using hot air, extrusion, or fusion techniques to form seamless, large-area liners, reducing labor costs and installation time. Their thin profile (0.2mm–3mm) also minimizes material usage compared to traditional concrete or clay liners.

6.Customizable & Adaptable Design Available in various thicknesses, widths, and material compositions, geomembranes can be tailored to project needs: HDPE geomembranes for high chemical resistance in landfills. LLDPE for flexibility in irregular terrains. PVC for cost-effective water retention projects. Custom coatings or reinforcements (e.g., geotextile composites) can enhance performance for specific challenges.

7.Eco-Friendly & Sustainable Solution Many geomembranes use recyclable polymers, and their long lifespan reduces the need for frequent replacements, minimizing environmental impact. In green projects, they enable water conservation in agriculture and protect ecosystems by preventing soil and groundwater contamination.

8.Compliance with International Standards Manufactured to strict norms (ASTM D3767, ISO 13954, GB/T 17643), geomembranes undergo rigorous testing for permeability, tensile strength, and weathering resistance. Third-party certifications ensure consistency and reliability for global projects.

9.Cost Savings Through Long-Term Performance While initial costs may be higher than traditional liners, geomembranes offer significant lifecycle savings: their durability reduces repair, replacement, and maintenance expenses, making them a cost-effective choice for long-term infrastructure.

10.Seamless Integration with Geosynthetic Systems Geomembranes can be combined with geotextiles, geogrids, or geocomposites to form multi-layer systems, enhancing stability, filtration, and protection—ideal for complex projects like landfill capping or slope stabilization.

BASIC DETAILS

Product Name: Geomembrane / Pond Liner

Available Thickness: 0.1mm, 0.2mm, 0.3mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm

Available Width: 4m, 5m, 5.8m, 6.0m, 7m, 8m, 10m

Standard Length: 50m / 100m per roll

Color Options: Black, White, Blue, Green

Surface Type: Smooth or Textured

Material Options: HDPE, LDPE, LLDPE

Certifications: ISO, TUV, SGS

Quality Control: Third-party testing and in-house laboratory inspection

Our high-density polyethylene (HDPE) geomembranes serve as an effective impermeable barrier against a wide range of liquids and solids. They feature outstanding chemical resistance, UV resistance, excellent impermeability, and high tensile and welded seam strength. These properties make them ideal for use as lining materials in various applications.

Available in a wide range of thicknesses and prices depending on model specifications, our geomembranes are produced with the following capacity:

Thickness: 0.2 mm to 5 mm

Width: 1 meter to 12 meters

They are especially suitable for seepage control in demanding environments and are widely used in aquaculture, water reservoirs, sewage treatment ponds, and other water containment or environmental protection projects.

Product Advantages

HDPE Geomembrane Applications

1. Aquaculture

HDPE geomembrane provides excellent anti-seepage performance, making it ideal for use in aquaculture environments such as fish ponds, shrimp ponds, and water tanks. It helps maintain water quality, reduces maintenance costs, and improves yield.

2. Landfills

HDPE geomembrane is the most widely used impermeable material in landfill engineering. It is commonly applied in landfill base liners, capping covers, and leachate collection ponds to prevent environmental contamination and groundwater pollution.

3. Water Treatment Systems

In water treatment and power plants, HDPE geomembrane is used to line adjustment tanks, sewage treatment ponds, and other components of water management systems, providing reliable containment and leak prevention.

4. Mining

In mining operations, HDPE geomembrane is used for heap leach pads, pregnant solution ponds, evaporation ponds, tailings containment, and other critical applications. It offers excellent chemical resistance and long-term durability in harsh mining environments.

Product Example

Product Specification

HDPE Geomembrane pond liner Technical Parameter

ASTM Standard geomembrane

| Spec Properties | Test method ASTM | GMS0.5 | GMS0.75 | GMS1.0 | GMS1.25 | GMS1.5 | GMS2.0 | GMS2.5 |

| Thickness | D5199 | 0.5mm | 0.75mm | 1.00mm | 1.25mm | 1.50mm | 2.00mm | 2.50mm |

| Density (≥ g/cc) | D1505 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 | 0.940 |

| Tensile Properties (Each direction) (≥) • yield strength • break strength • yield elongation • break elongation | D 6693 Type IV | 8 kN/m 14kN/m 12% 700% | 11 kN/m 20kN/m 12% 700% | 15 kN/m 27 kN/m 12% 700% | 18 kN/m 33 kN/m 12% 700% | 22 kN/m 40 kN/m 12% 700% | 29 kN/m 53 kN/m 12% 700% | 37kN/m 67kN/m 12% 700% |

| Tear Resistance (≥) | D 1004 | 64 N | 93 N | 125 N | 156 N | 187 N | 249 N | 311 N |

| Puncture Resistance (≥) | D 4833 | 160 N | 240 N | 320 N | 400 N | 480 N | 640 N | 800 N |

| Stress Crack Resistance (≥) | D 5397 | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. |

| Carbon Black Content | D 1603 | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

| Carbon Black Dispersion | D 5596 | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) | Note(1) |

| Oxidative Induction Time (OIT) (≥) (a)Standard OIT - or - (b)High Pressure OIT | D 3895 D 5885 | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. | 100 min. 400 min. |

FAQ

Q:Can you send samples?

A:Yes,we are very happy to provide you with free samples to check the quality of our products.

Q:Are you a manufacturer or a trading company?

A:Our company located in Hefei,Anhui Province,with are gistered capital of 52 miion yuan.It is a professiona lmanufacturer of geomembrane,geotextile,geogrid and other products.So we have the competitive price with best quality.

Q:Can you produce the product according to customers' requirements?

A:Sure,we are professional manufacturer,OEM and ODM are both welcome.

Q:How long is the delivery time?

A:General within 3-7days after received the deposit

Q:How to control product quality?

A:Our factory adopts lean management,products from the beginning to the end of the production process have strict quality control.All products must be strictly tested before packing and shipping