| Width: | |

|---|---|

| Color: | |

| Roll length: | |

| Availability: | |

| Quantity: | |

ZL-TGGS-GS

zhongloo

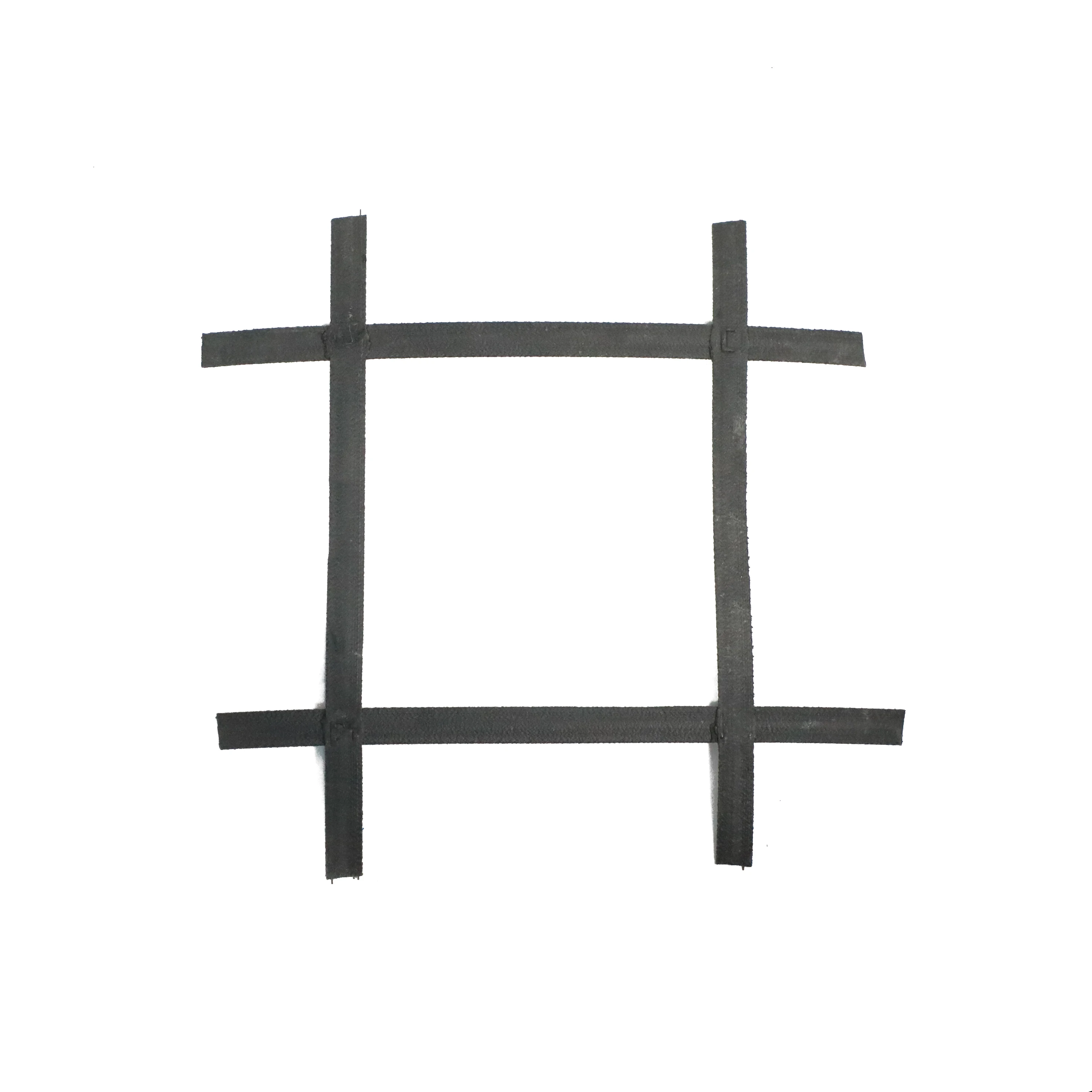

Steel Plastic Geogrid Driveway Geogrid Gravel Grid Ground Grid Biaxial Steel Plastic Geogrid Price For Road Construction

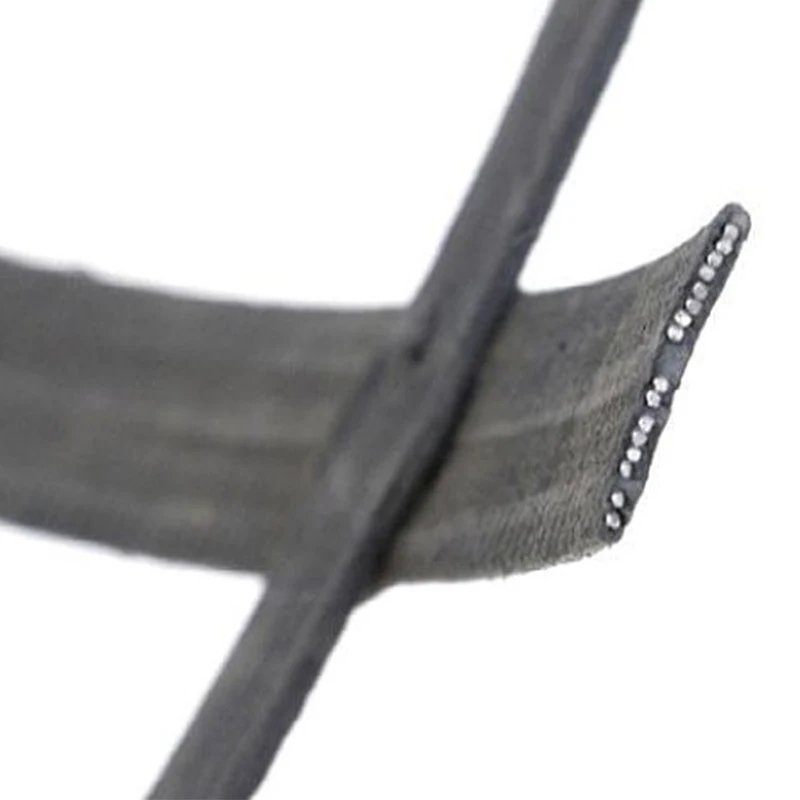

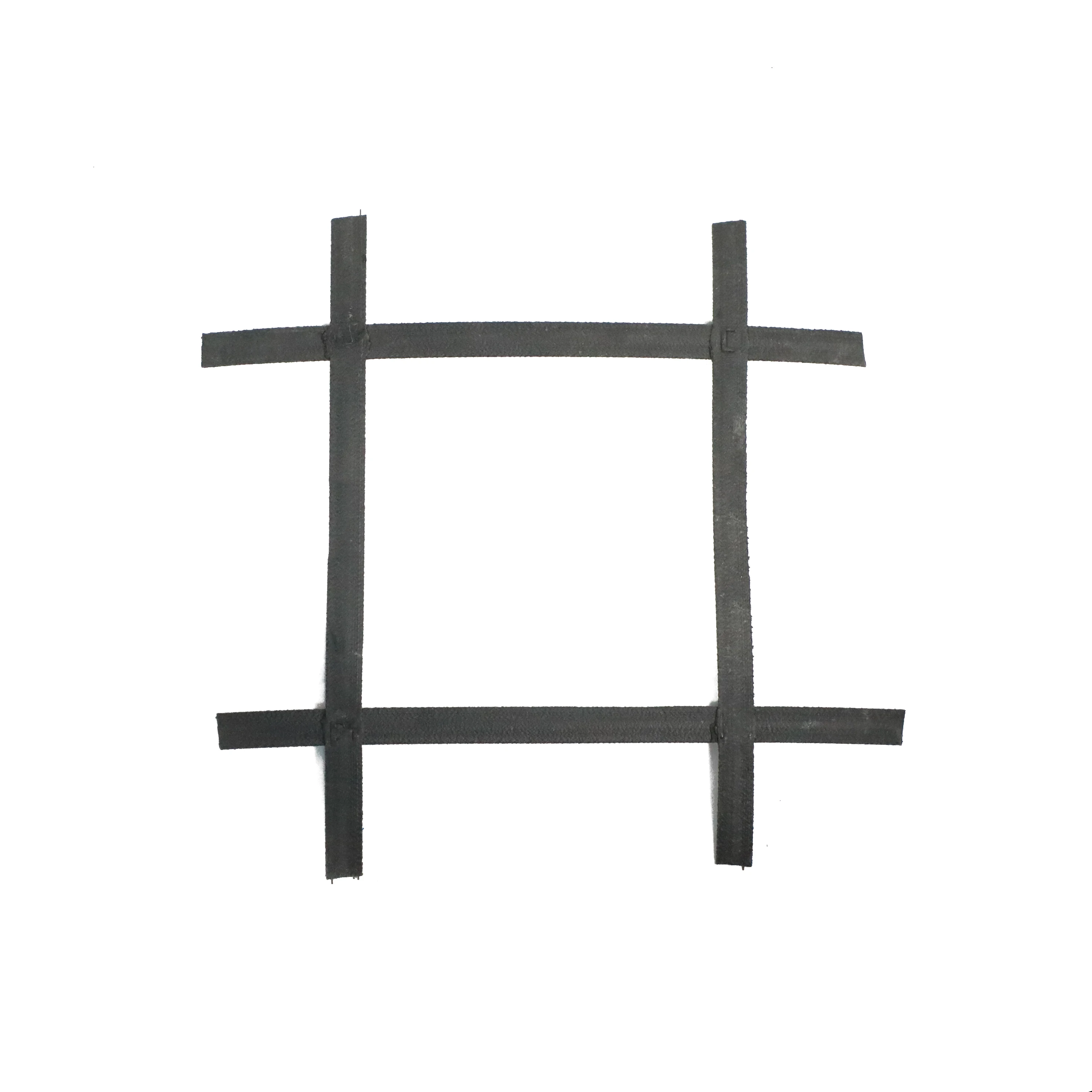

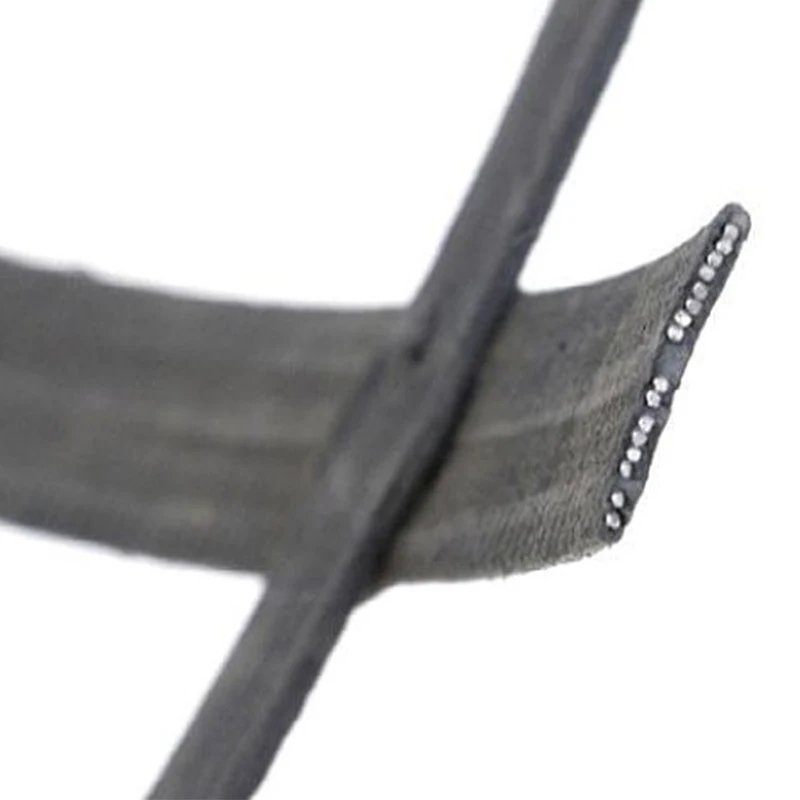

Steel-Plastic Geogrid is made from high-strength steel wire (or other high-performance fibers) that undergoes specialized surface treatment. The treated wire is then combined with polyethylene (PE) or polypropylene (PP) and other additives, and extruded into high-tensile strength strips with a rough, embossed surface to enhance friction and bonding with soil.

These reinforced geotechnical strips are arranged in both longitudinal and transverse directions at specified intervals or clamped configurations. The structure is then formed using advanced bonding and welding technology, resulting in a high-strength, durable geogrid suitable for soil reinforcement and load-bearing applications.

POLYESTER GEOGRID

Polyester geogrid is an advanced geosynthetic material designed to reinforce road surfaces and subgrades. It is composed of high-strength polyester yarns coated with an inorganic sizing agent, providing excellent mechanical properties and durability.

Features:

High tensile strength with low elongation

Superior tear resistance

Strong interlocking with gravel and soil

Excellent corrosion resistance, aging resistance, and alkali resistance

Application:

Widely used for reinforcing soft soils in railway and roadway construction, improving load distribution and extending pavement lifespan.

Product Features

When the bidirectional strength is used on the surface of the plastic, the rid is pressed into rough pattern to reinforce the roughness of geogrid surface, increase the friction factor between the geogrid and soil.

This geogrid is low cost and easy to construct, easy to pave, lap, locate, avoid the repetition and cross, so shorten the construction period obviously.

High strength, small creep deformation, suitable for various environmental soils.

Improve the interlocking and the occlusion of the reinforcement supporting surface.

5. The construction, first of all to use small diameter sand or clay levelingbase, and then laid the geomembrane. The geomembrane should not be stretched too tight, and the part of the soil bured at both ends is corrugated. A transitional layer of about 10cm is laid on the geomembrane with sand or clay.

Q:Can you send samples? A:Yes,we are very happy to provide you with free samples to check the quality of our products.

Steel Plastic Geogrid Driveway Geogrid Gravel Grid Ground Grid Biaxial Steel Plastic Geogrid Price For Road Construction

Steel-Plastic Geogrid is made from high-strength steel wire (or other high-performance fibers) that undergoes specialized surface treatment. The treated wire is then combined with polyethylene (PE) or polypropylene (PP) and other additives, and extruded into high-tensile strength strips with a rough, embossed surface to enhance friction and bonding with soil.

These reinforced geotechnical strips are arranged in both longitudinal and transverse directions at specified intervals or clamped configurations. The structure is then formed using advanced bonding and welding technology, resulting in a high-strength, durable geogrid suitable for soil reinforcement and load-bearing applications.

POLYESTER GEOGRID

Polyester geogrid is an advanced geosynthetic material designed to reinforce road surfaces and subgrades. It is composed of high-strength polyester yarns coated with an inorganic sizing agent, providing excellent mechanical properties and durability.

Features:

High tensile strength with low elongation

Superior tear resistance

Strong interlocking with gravel and soil

Excellent corrosion resistance, aging resistance, and alkali resistance

Application:

Widely used for reinforcing soft soils in railway and roadway construction, improving load distribution and extending pavement lifespan.

Product Features

When the bidirectional strength is used on the surface of the plastic, the rid is pressed into rough pattern to reinforce the roughness of geogrid surface, increase the friction factor between the geogrid and soil.

This geogrid is low cost and easy to construct, easy to pave, lap, locate, avoid the repetition and cross, so shorten the construction period obviously.

High strength, small creep deformation, suitable for various environmental soils.

Improve the interlocking and the occlusion of the reinforcement supporting surface.

5. The construction, first of all to use small diameter sand or clay levelingbase, and then laid the geomembrane. The geomembrane should not be stretched too tight, and the part of the soil bured at both ends is corrugated. A transitional layer of about 10cm is laid on the geomembrane with sand or clay.

Q:Can you send samples? A:Yes,we are very happy to provide you with free samples to check the quality of our products.