| Material: | |

|---|---|

| Width: | |

| Color: | |

| Length: | |

| Availability: | |

| Quantity: | |

ZL-TGGS

zhongloo

Steel Plastic Geogrid Driveway Geogrid Gravel Grid Ground Grid Biaxial Steel Plastic Geogrid Price For Road Construction

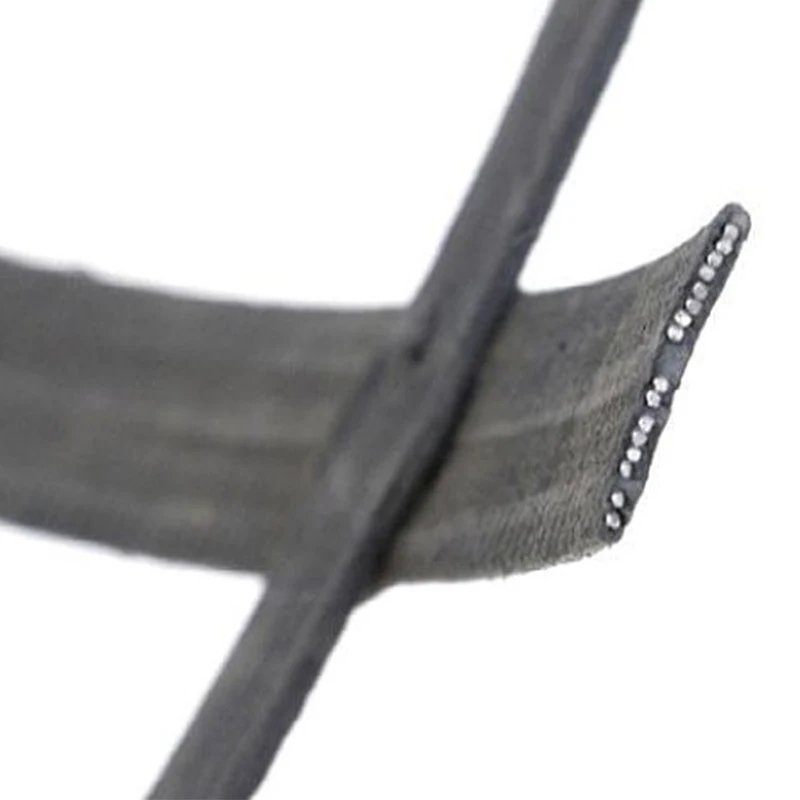

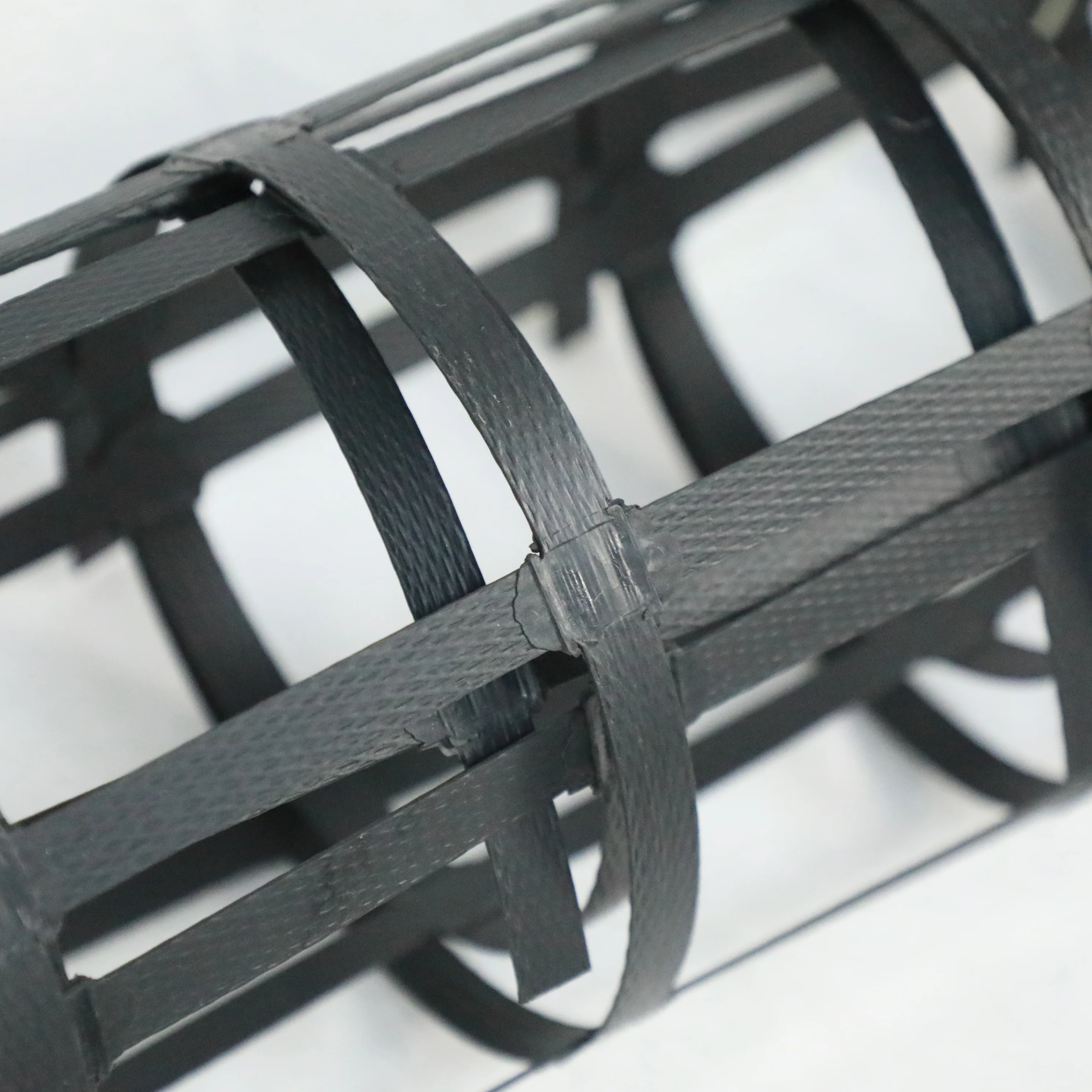

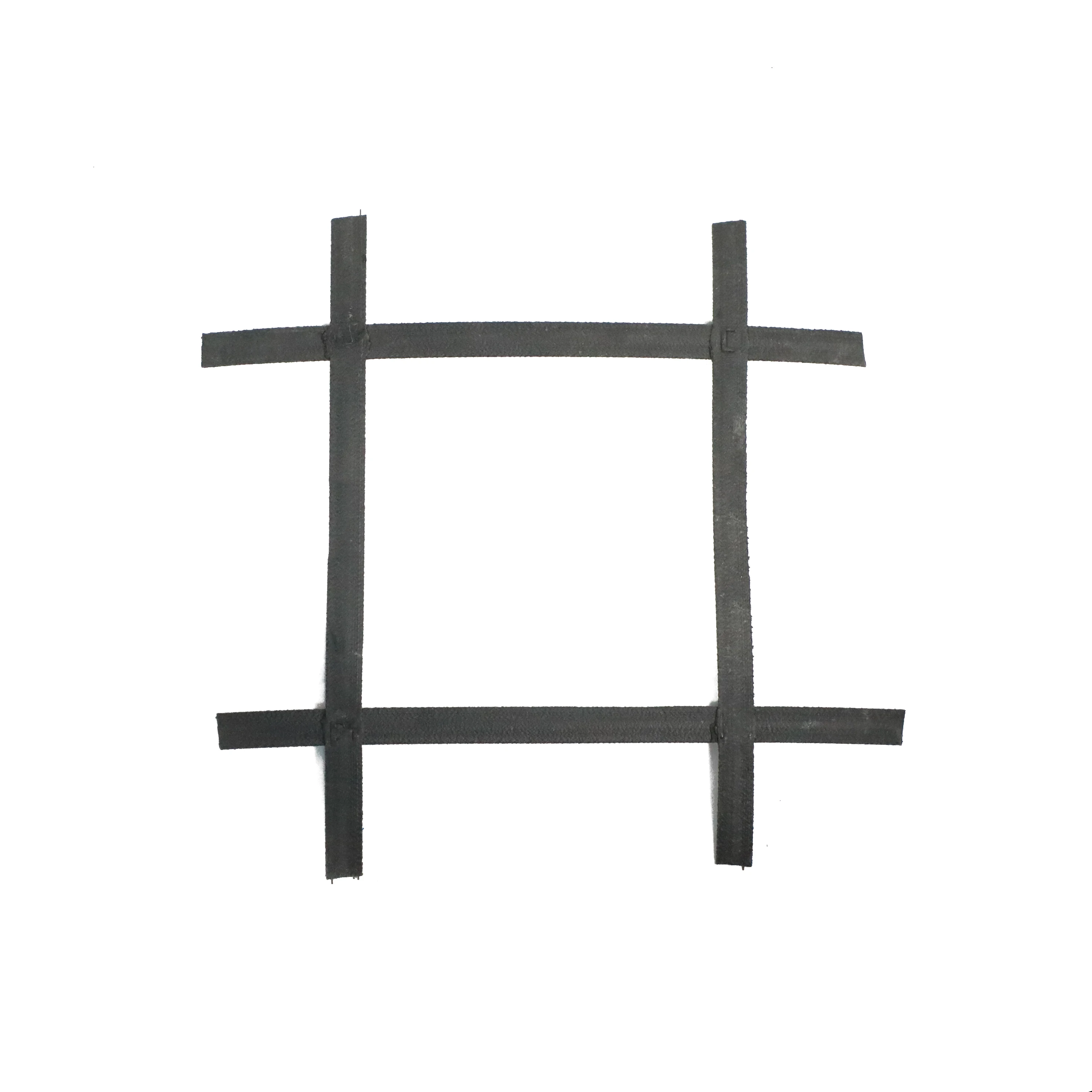

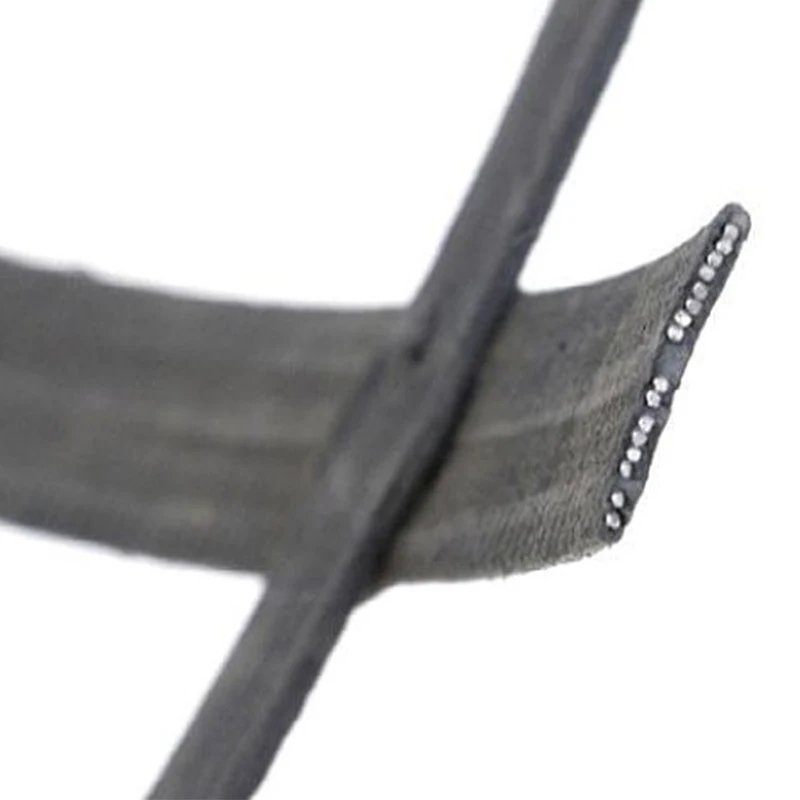

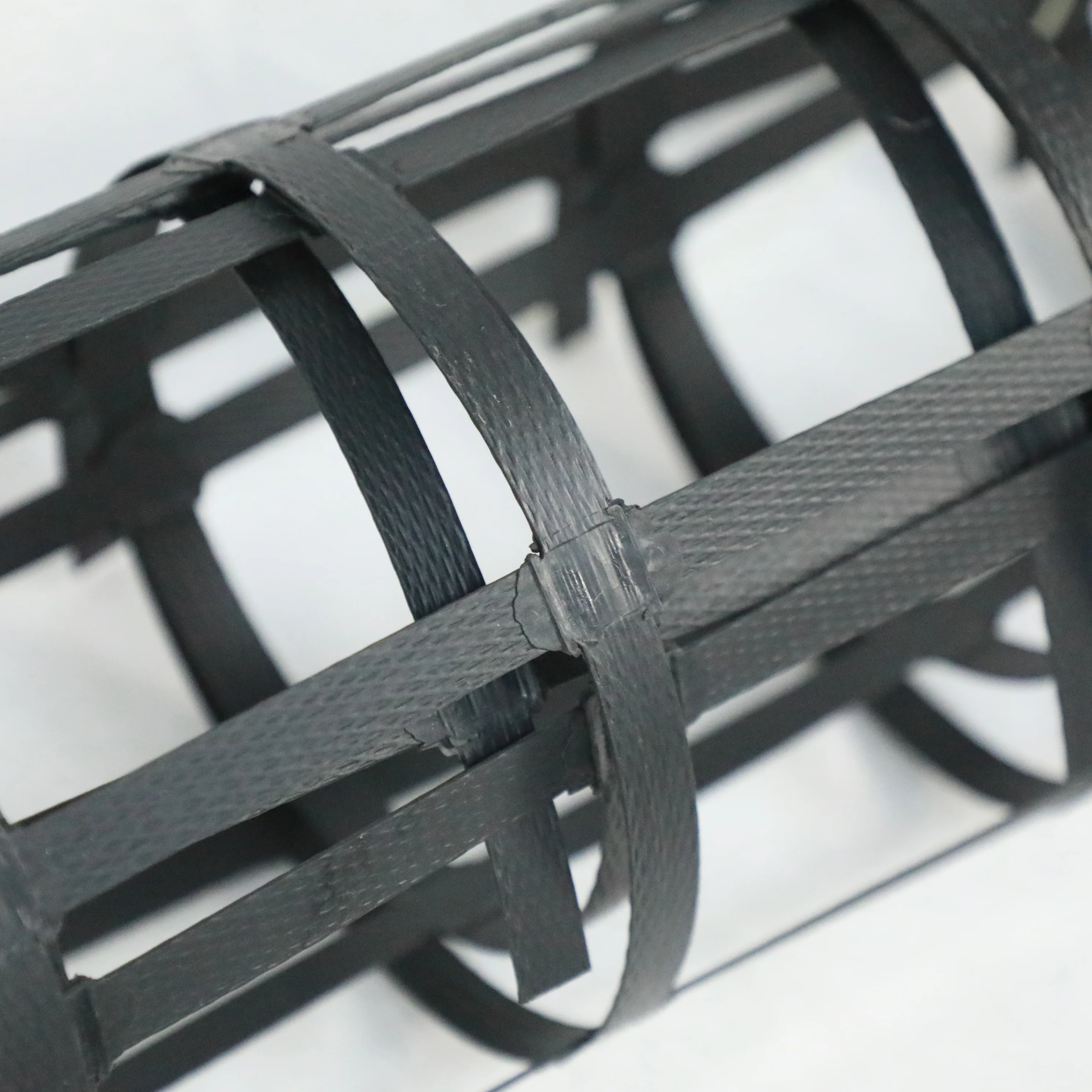

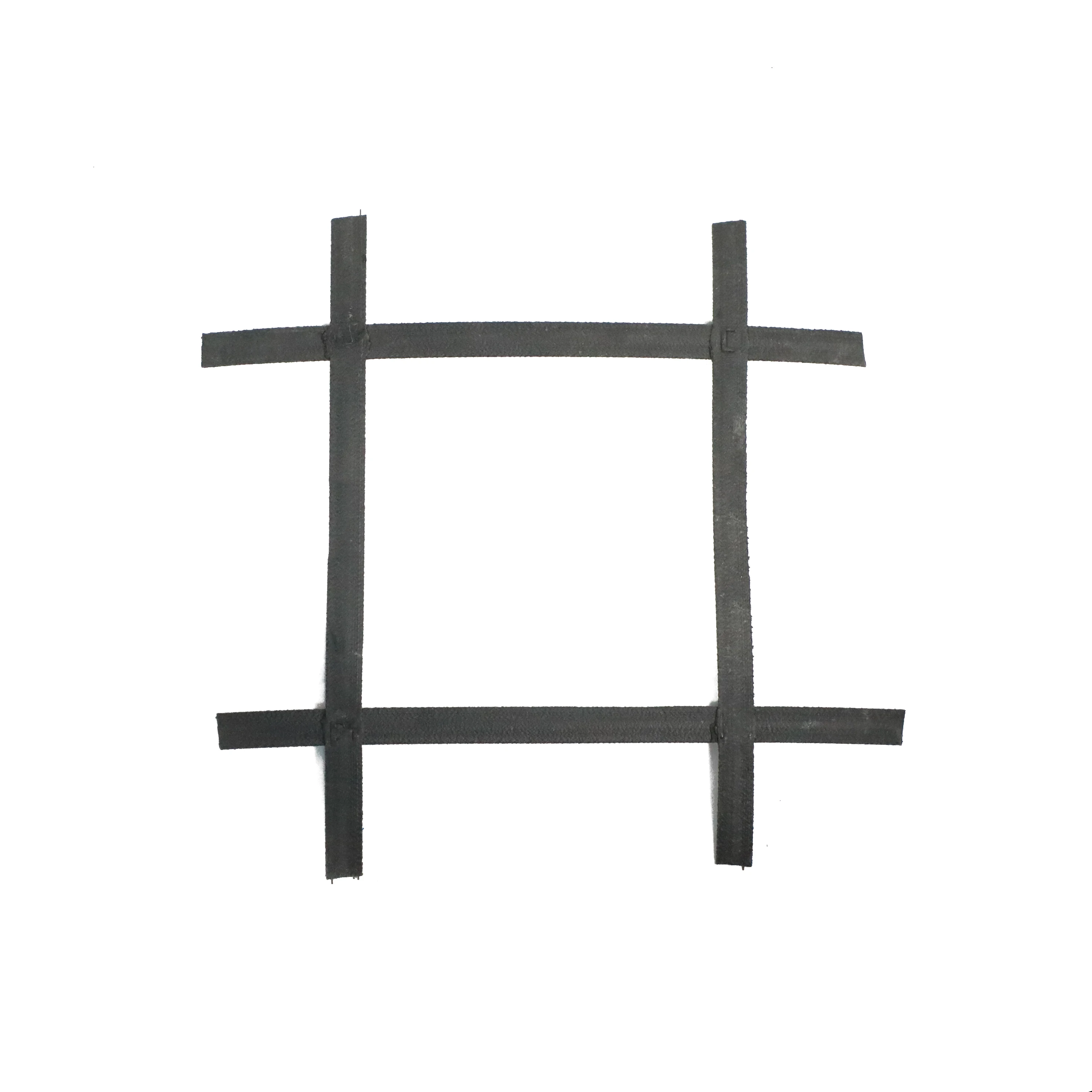

The steel plastic composite geogrid is a high-performance reinforcement material made by embedding high-strength steel wires-specially treated for durability-into a polyethylene (PE) or polypropylene (PP) matrix through extrusion, along with functional additives. The steel wires are woven in both longitudinal and transverse directions, forming a grid structure with extremely high tensile modulus under pre-tension conditions.

The vertical and horizontal ribs work together to create a strong interlocking effect with the surrounding soil, significantly improving soil stability and bearing capacity. During the manufacturing process, the surface of the plastic strips is textured with rough patterns to increase surface roughness, thereby enhancing the friction coefficient and bonding between the geogrid and the soil.

This composite geogrid also exhibits excellent resistance to acids and a wide range of chemical substances, making it ideal for harsh environmental conditions in road, railway, slope protection, and foundation engineering applications.

Product Features

Q:Can you send samples?

A:Yes,we are very happy to provide you with free samples to check the quality of our products.

Q:Are you a manufacturer or a trading company?

A:Our company located in Hefei,Anhui Province,with are gistered capital of 52 miion yuan.It is a professiona lmanufacturer of geomembrane,geotextile,geogrid and other products.So we have the competitive price with best quality.

Q:Can you produce the product according to customers' requirements?

A: Sure,we are professional manufacturer,OEM and ODM are both welcome.

Q:How long is the delivery time?

A: General within 3-7days after received the deposit.

Q: How to control product quality?

A: Our factory adopts lean management,products from the beginning to the end of the production process have strict quality control.All products must be strictly tested before packing and shipping.

Steel Plastic Geogrid Driveway Geogrid Gravel Grid Ground Grid Biaxial Steel Plastic Geogrid Price For Road Construction

The steel plastic composite geogrid is a high-performance reinforcement material made by embedding high-strength steel wires-specially treated for durability-into a polyethylene (PE) or polypropylene (PP) matrix through extrusion, along with functional additives. The steel wires are woven in both longitudinal and transverse directions, forming a grid structure with extremely high tensile modulus under pre-tension conditions.

The vertical and horizontal ribs work together to create a strong interlocking effect with the surrounding soil, significantly improving soil stability and bearing capacity. During the manufacturing process, the surface of the plastic strips is textured with rough patterns to increase surface roughness, thereby enhancing the friction coefficient and bonding between the geogrid and the soil.

This composite geogrid also exhibits excellent resistance to acids and a wide range of chemical substances, making it ideal for harsh environmental conditions in road, railway, slope protection, and foundation engineering applications.

Product Features

Q:Can you send samples?

A:Yes,we are very happy to provide you with free samples to check the quality of our products.

Q:Are you a manufacturer or a trading company?

A:Our company located in Hefei,Anhui Province,with are gistered capital of 52 miion yuan.It is a professiona lmanufacturer of geomembrane,geotextile,geogrid and other products.So we have the competitive price with best quality.

Q:Can you produce the product according to customers' requirements?

A: Sure,we are professional manufacturer,OEM and ODM are both welcome.

Q:How long is the delivery time?

A: General within 3-7days after received the deposit.

Q: How to control product quality?

A: Our factory adopts lean management,products from the beginning to the end of the production process have strict quality control.All products must be strictly tested before packing and shipping.